Basic Structure and Classification of Zippers[^1][^1]: Understanding zipper classifications can help you choose the right type for your project.

1. Basic Structure of a Zipper -- Every Component is Vital

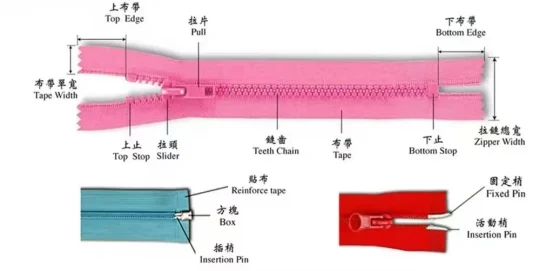

1.A zipper is a fastener consisting of two flexible tape strips with interlocking elements (teeth) and a slider that allows the zipper to be repeatedly opened and closed. The structure of a zipper is shown in the diagram below.

A detailed explanation of the zipper components shown in the diagram is as follows:

| Component Name | Description |

|---|---|

| Tape | A flexible woven band made from cotton, chemical fibers, or a blend, used to carry the teeth and other zipper components. |

| teeth chain | The teeth of the zipper, made from materials like metal or plastic and shaped through processing. |

| Top Stop | A fixed component on the tape that prevents the slider from sliding off when the zipper is fully closed. |

| Bottom Stop | A fixed component on the chain that prevents the slider from sliding off when the zipper is fully open and ensures the two sides of the chain do not separate completely. |

| Back & Forth Head Tape | The part of the tape without teeth. The end with the top stop is the front head tape, and the end with the bottom stop is the back head tape. |

| Pin (Separable Pin) | A tubular component fixed to the end of an open-end zipper, used to separate the two sides of the chain completely. |

| Box (Retainer) | A square component fixed to the end of an open-end zipper, used to separate the two sides of the chain completely. |

| Two-Pin Slider | A tubular component used with a pin on a double-open-end zipper. |

| Strengthened Tape | A composite sheet used to reinforce the connection between the pin, box, and the tape, increasing the zipper's lifespan. |

| Slider | The moving component that engages and disengages the teeth. |

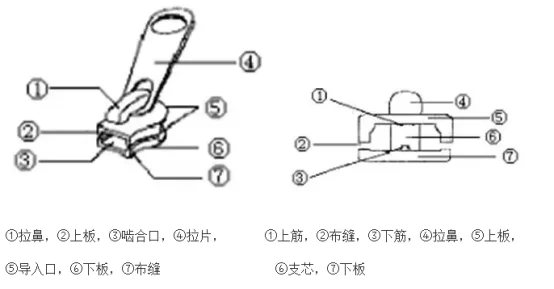

2. Slider Head

The main body of the slider. It has two entry slots and one exit slot for the teeth. It consists of an upper and lower plate. The upper plate has a pull tab, which is connected to the lower plate via a pivot pin. For nylon zippers, the inner sides of the upper and lower plates have upper and lower beads.

Types of Sliders

Sliders come in many varieties. The most common types are auto-lock, pin-lock, non-lock, and movable double-open-end sliders. An introduction to each type is provided below.

-

(1) Auto-Lock Slider (A/L)

-

Also known as a self-locking slider. It has a small locking tab on the pull tab that automatically engages between the teeth under spring tension, locking the slider. To open or close the zipper, the pull tab is lifted to disengage the tab.

-

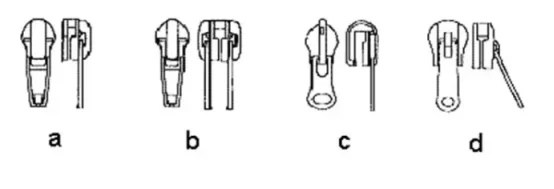

a. One-Way A/L Slider(as shown in Figure a below): An auto-lock slider with one pull tab on the upper plate.

-

b. Two-Way A/L Slider(as shown in Figure b below): An auto-lock slider with one pull tab on both the upper and lower plates.

-

c. Reversible A/L Slider(as shown in Figure c below): An auto-lock slider where the pull tab can be wrapped around the upper and lower plates(as shown in Figure c below).

-

(2) Pin-Lock Slider(as shown in Figure d below):The pull tab has one or two pins. When the pull tab is pressed down, the pins insert into the teeth, locking the slider in place.

-

(3) Non-Lock Slider (N/L)

-

A slider without a locking function. It comes in single and double pull varieties.

-

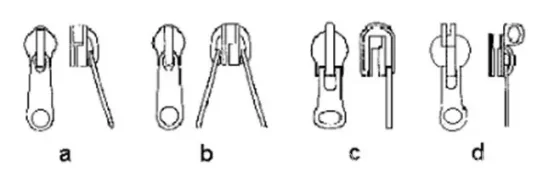

a. One-Way N/L Slider(as shown in Figure a below): A non-lock slider with one pull tab on the upper plate.

-

b. Two-Way N/L Slider(as shown in Figure b below): A non-lock slider with one pull tab on both the upper and lower plates.

-

c. Reversible N/L Slider(as shown in Figure c below): A non-lock slider where the pull tab can be wrapped around the upper and lower plates.

-

d. N/L Slider with a Lock Hole(as shown in Figure d below): A non-lock slider with one or two lock holes on the upper plate, used on "O" shaped zippers to lock the two sliders together with a separate lock after the zipper is closed.

-

(4) Movable Double-Open-End Slider

-

A slider used on double-open-end zippers that can act as a box and a positioning element.

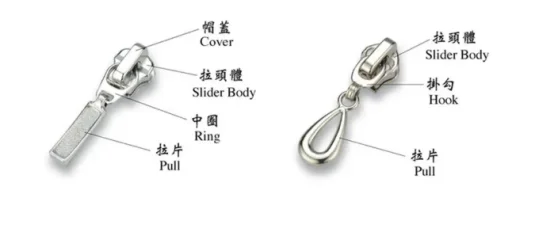

3. Pull Tab (Puller)

The pull tab is an important component of the slider. Besides its functional role, it is highly decorative and often serves as a brand carrier. It can be designed into various geometric shapes and connected directly to the slider body or via an intermediate connector (the connecter). Pull tabs are made from various materials, such as metal, injection-molded plastic, leather, and rhinestones.

- a. Silicone and PVC Pull Tabs: Soft, comfortable to the touch, and available in a wide range of colors.

- b. Metal Pull Tabs

- c. Plastic Pull Tabs: Made from injection-molded materials like TPU, TP, POM, and PP. Typically single-colored, but can also be two-colored.

- d. Rhinestone, Oil Drop, and Epoxy Pull Tabs

- e. Leather Pull Tabs

II. Classification of Zippers

Zippers come in many varieties. Here we introduce the three main classification methods: by type, material, and specification.

A. By Type: Closed-End and Open-End

- Closed-End Zipper

- A zipper that cannot be fully separated when opened.

- (1) One-Way Closed-End Zipper: A closed-end zipper with one slider.

- (2) Two-Way Closed-End Zipper: A closed-end zipper with two sliders that can be opened in opposing directions (forming an "O" or "X" shape).

- Open-End Zipper

- A zipper that can be fully separated when opened.

- (1) One-Way Open-End Zipper: An open-end zipper with one slider. When the slider reaches the end, the pin can be pulled out from the slider and box to separate the two sides. The zipper is closed by re-inserting the pin into the box through the slider.

- (2) Two-Way Open-End Zipper: An open-end zipper with two sliders. When both sliders reach the end, the pin can be pulled out to separate the two sides. The zipper is closed by inserting the pin back into the box through both sliders.

B. By Material: Nylon, Injection-Molded, and Metal

-

Nylon Zipper

-

A zipper where the teeth are made from a single filament fixed to the tape through a molding process. It is lightweight, flexible, and has good bendability, making it suitable for sportswear, children's clothing, and lightweight fabrics. It can also be made as an invisible zipper, offering both comfort and aesthetics.

-

Injection-Molded Zipper

-

Made through an injection-molding process, featuring large, well-defined teeth. It is durable, washable, and available in a wide range of colors, making it suitable for heavy coats, luggage, and functional bags. Attention should be paid to low-temperature brittleness and color consistency.

-

Metal Zipper

-

A zipper made with metal teeth, including materials such as aluminum, zinc alloy, and copper (brass, white copper, antique copper, red copper, etc.).

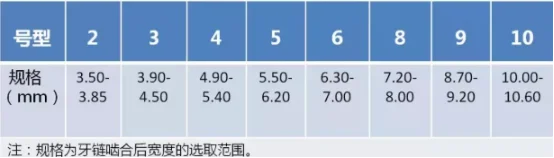

C. By Specification

The specification of a zipper refers to the width in millimeters when the two sides of the chain are fully interlocked. Common sizes include #3, #4, #5, #7, #8, #9, up to #20. The size number is proportional to the size of the teeth, with #3 to #7 being the most commonly used.

The following table shows common zipper specifications and types: