Are you struggling with broken zipper pullers or confused about which type to choose for your project? You're not alone in this common fastener dilemma.

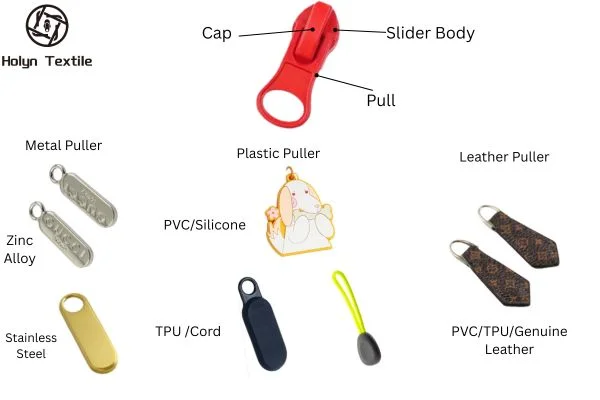

A zipper puller1 is the small handle attached to the zipper slider that allows you to open and close zippers. The right puller choice depends on your application, material preferences, and durability requirements.

I've spent years working with garment manufacturers and designers who face these same challenges. Through my experience at Holyn Textile, I've learned that understanding zipper hardware basics2 can save you time, money, and frustration. Let me share what I've discovered about these essential fastener components.

I've spent years working with garment manufacturers and designers who face these same challenges. Through my experience at Holyn Textile, I've learned that understanding zipper hardware basics2 can save you time, money, and frustration. Let me share what I've discovered about these essential fastener components.

What is a Zipper Puller? Definition and Function

Do you know the exact role this small but crucial piece of zipper hardware plays in your daily life?

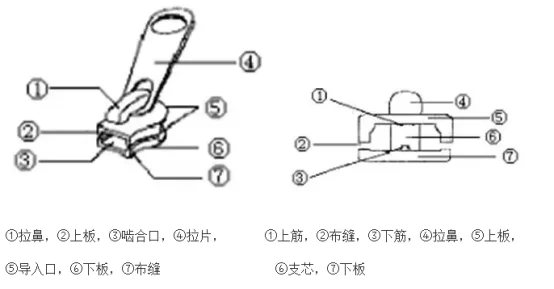

A zipper puller1 definition encompasses the movable handle that connects to the zipper slider, enabling users to operate the closure mechanism by moving the slider up and down the zipper teeth.

When I first started working with textile hardware, I thought all zipper parts were basically the same. I was wrong. The zipper puller is actually a complex component that must balance functionality with aesthetics. It consists of several parts: the pull tab (what you grab), the connector (which attaches to the slider), and sometimes decorative elements.

When I first started working with textile hardware, I thought all zipper parts were basically the same. I was wrong. The zipper puller is actually a complex component that must balance functionality with aesthetics. It consists of several parts: the pull tab (what you grab), the connector (which attaches to the slider), and sometimes decorative elements.

The function goes beyond just providing a grip point. A quality zipper puller distributes the pulling force evenly across the slider mechanism. This prevents damage to the zipper teeth and ensures smooth operation. I've seen countless products fail because manufacturers chose cheap pullers that broke under normal use. The puller also serves as a design element, often becoming the most visible part of the zipper system.

In my work with clients, I always explain that the zipper puller is like the steering wheel of a car - it's your primary interface with the entire closure system. Without it, even the best zipper becomes unusable. This is why choosing the right puller is so important for your project's success.

Different Types of Zipper Pullers Explained

Are you aware of how many different types of zipper pullers3 exist and which one suits your specific needs?

Types of zipper pullers include standard pulls, ring pulls, slider pulls without separate tabs, and custom decorative pulls, each designed for specific applications and user preferences.

Through my experience helping clients choose the right fastener components, I've encountered virtually every puller type available. Standard pulls are the most common - these attach directly to the slider and come in countless shapes and sizes. I remember working with a sportswear brand that needed pulls that wouldn't catch on fabric during intense movement.

Through my experience helping clients choose the right fastener components, I've encountered virtually every puller type available. Standard pulls are the most common - these attach directly to the slider and come in countless shapes and sizes. I remember working with a sportswear brand that needed pulls that wouldn't catch on fabric during intense movement.

Cord pulls use a flexible string or cord connection, making them ideal for situations where the puller needs to lie flat or move out of the way. These are popular in outdoor gear and children's clothing. Ring pulls offer easy grip and are often used in luggage and bags where durability is key.

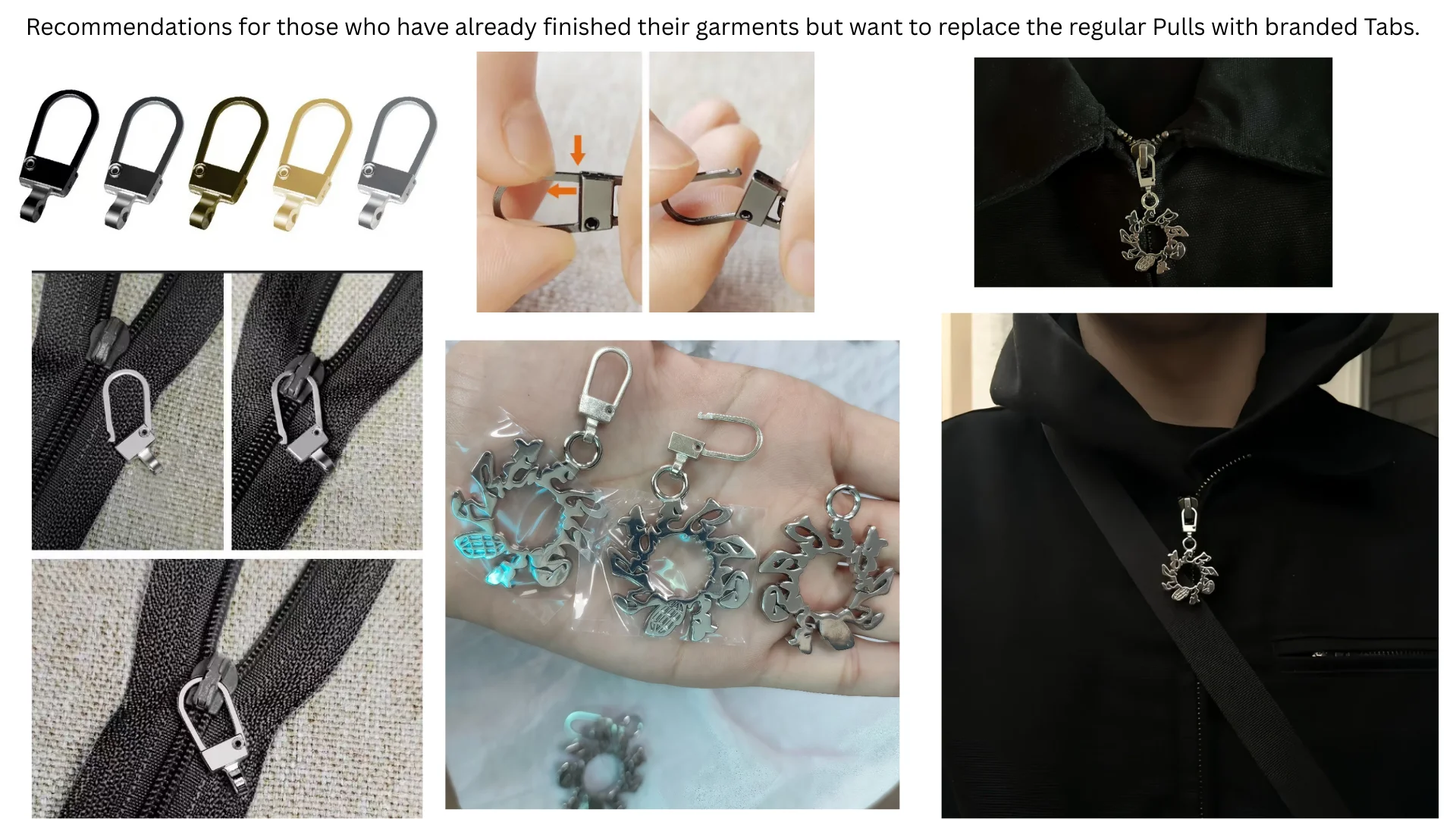

Some sliders come without separate pullers - these integrated designs4 are common in invisible zippers where aesthetics matter most. Then there are custom decorative pulls that serve as brand elements or design features. I've worked with fashion brands that treat their zipper pulls like jewelry, creating unique shapes and finishes that become signature elements.

The key is matching the puller type to your application. Each serves different user needs and aesthetic goals, and understanding these differences helps you make better choices for your projects.

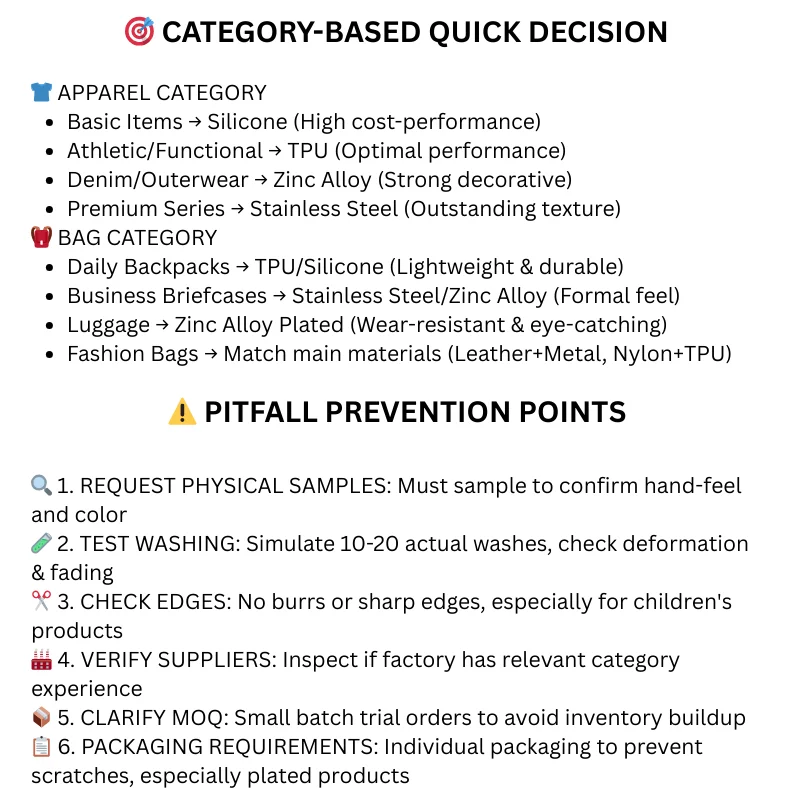

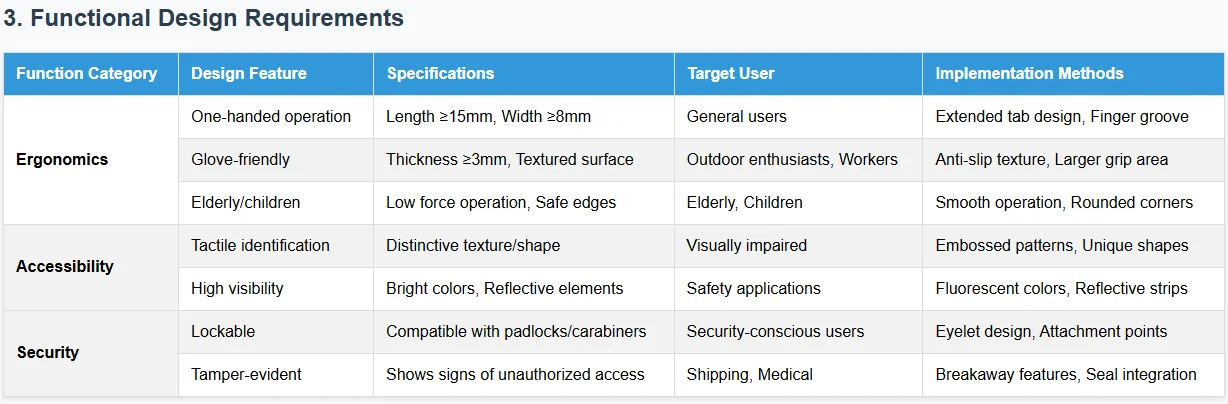

How to Choose the Right Zipper Puller for Your Project?

What factors should guide your zipper puller selection to ensure both functionality and user satisfaction?

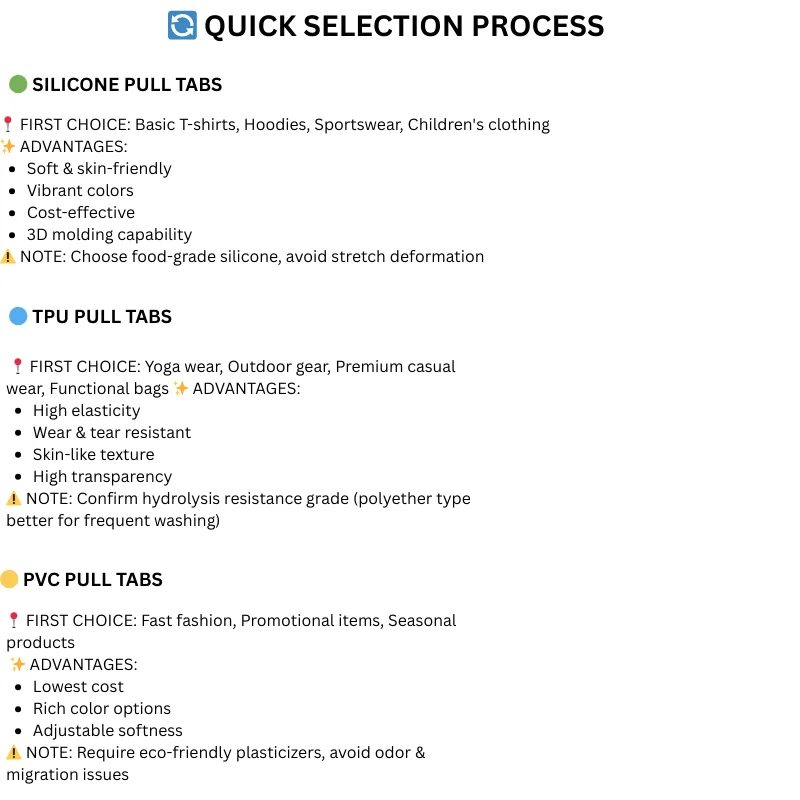

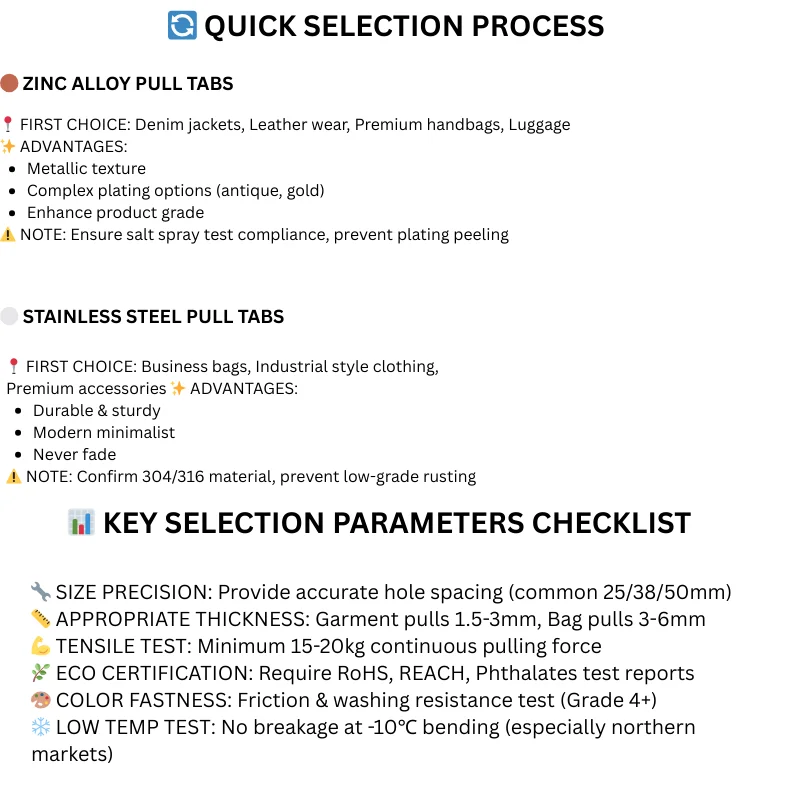

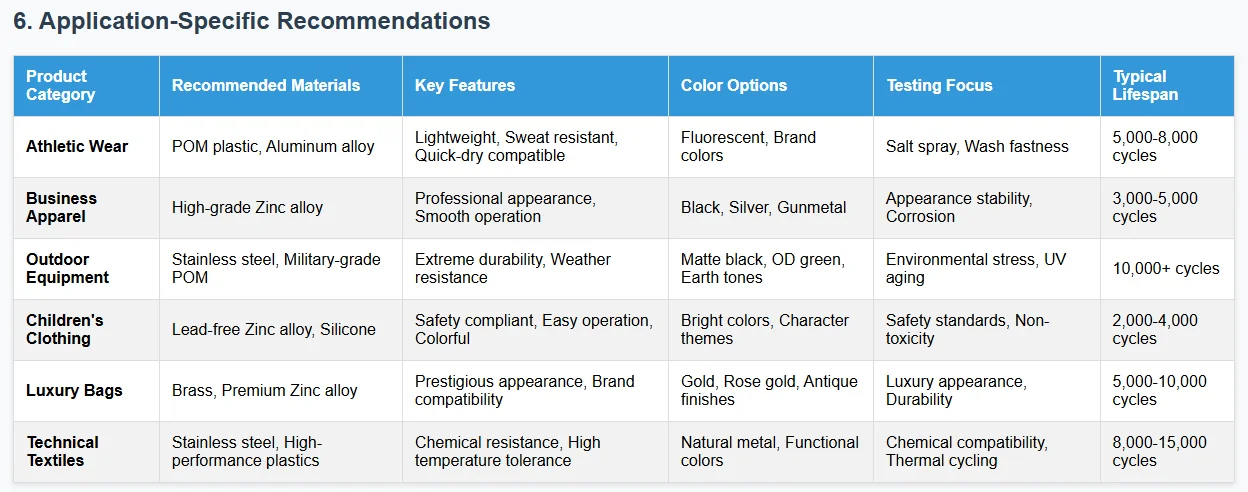

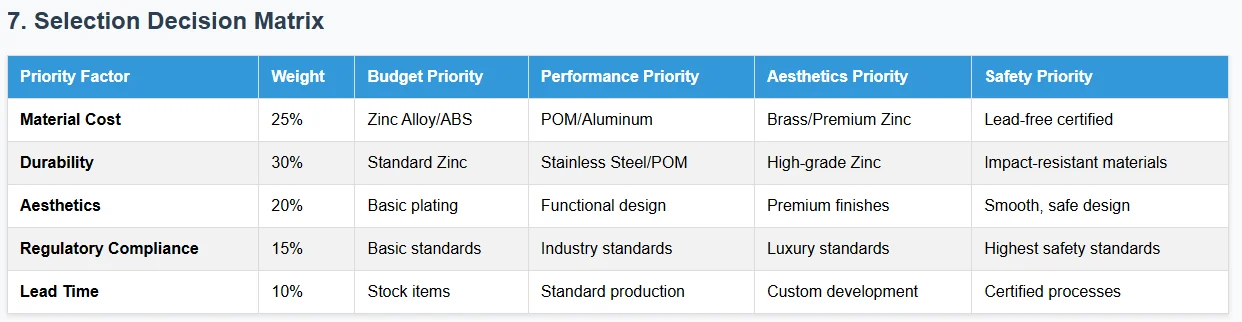

Zipper puller selection depends on your application requirements, user demographics, durability needs, aesthetic goals, and budget constraints. Consider usage frequency, environmental conditions, and brand requirements.

I always tell my clients that zipper puller selection is like choosing the right tool for a job. Recently, I worked with a children's clothing manufacturer who needed pullers that small hands could easily grip but that wouldn't pose safety risks. We selected larger, rounded pulls with smooth edges.

I always tell my clients that zipper puller selection is like choosing the right tool for a job. Recently, I worked with a children's clothing manufacturer who needed pullers that small hands could easily grip but that wouldn't pose safety risks. We selected larger, rounded pulls with smooth edges.

Consider your user first. Elderly users need larger, easier-to-grip pulls. Athletes need pulls that won't interfere with performance. Fashion applications might prioritize appearance over functionality. I remember a luxury handbag client who insisted on metal pulls that matched their hardware exactly, even though it cost more.

Environmental factors matter too. Outdoor gear needs pulls that resist corrosion and temperature extremes. I've seen plastic pulls become brittle in cold weather and metal ones become too hot to touch in summer sun. Swimming and activewear require pulls that resist chlorine and salt water damage.

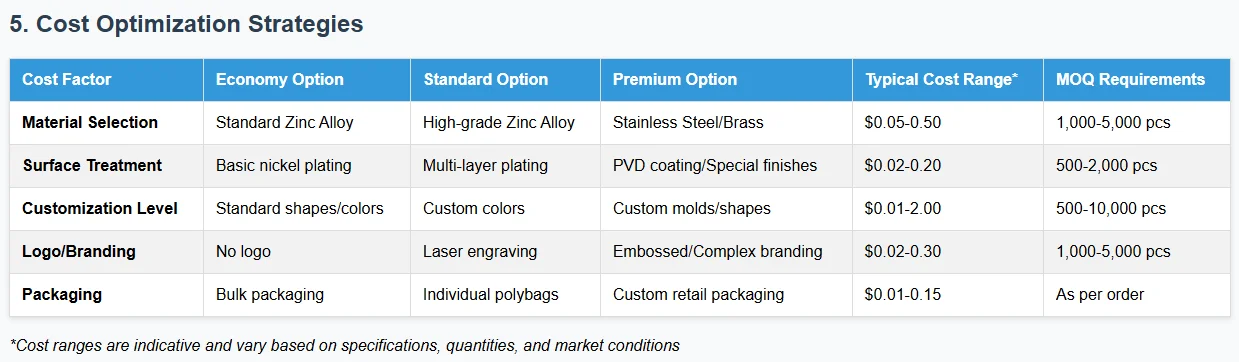

Your production volume5 affects options too. Custom pulls require minimum orders, while standard options offer more flexibility. Budget always plays a role, but I advise clients to consider the cost of failures and returns when choosing cheaper options. A good puller that costs slightly more upfront often saves money long-term through reduced warranty claims and happier customers.

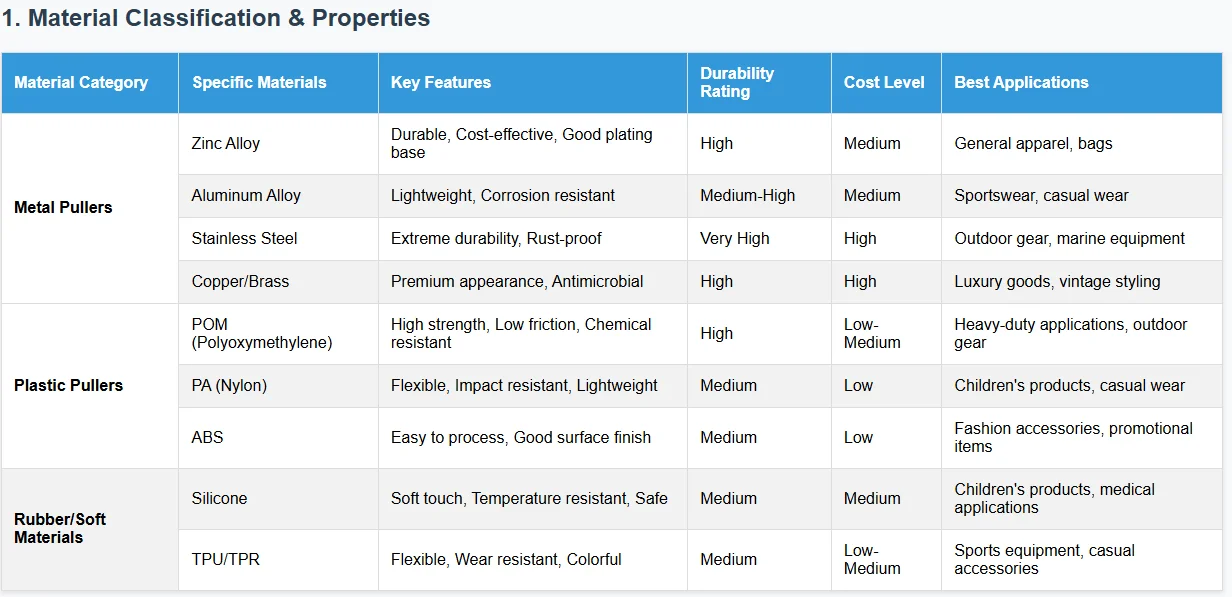

Zipper Puller Materials: Metal vs Plastic Comparison

How do different zipper puller materials perform in real-world applications, and which offers the best value for your needs?

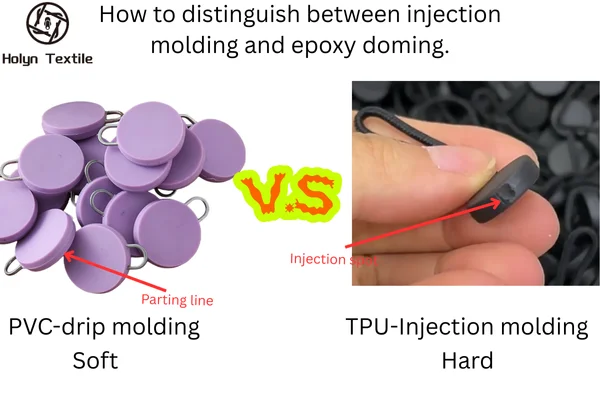

Metal zipper puller options include stainless steel and zinc alloy for durability, while plastic zipper puller6 materials like PVC, TPU, and silicone offer lightweight, cost-effective solutions with design flexibility.

In my years of working with garment accessories, I've learned that there's no universally "best" material - only the right material for each application. Let me share what I've discovered about each option:

| Material | Durability | Weight | Cost | Temperature Resistance | Design Flexibility |

|---|---|---|---|---|---|

| Stainless Steel | Excellent | Heavy | High | Excellent | Limited |

| Zinc Alloy | Very Good | Medium | Medium | Good | Good |

| PVC | Good | Light | Low | Fair | Excellent |

| TPU | Very Good | Light | Medium | Very Good | Excellent |

| Silicone | Good | Light | Medium | Excellent | Good |

I remember working with a client who insisted on stainless steel pulls for outdoor gear. The durability was perfect, but customers complained about the weight and cold touch in winter conditions. We switched to TPU with a textured finish, solving both problems.

For decorative zipper pulls, I often recommend zinc alloy because it takes plating well and allows detailed designs. The electroplating process I mentioned earlier becomes crucial here - we always test our plated pulls in salt water to ensure the coating won't fail. When laser engraving logos, I tell clients that red color indicates environmentally friendly materials7, while white indicates nickel content.

The key is matching material properties to your specific needs rather than assuming expensive always means better.

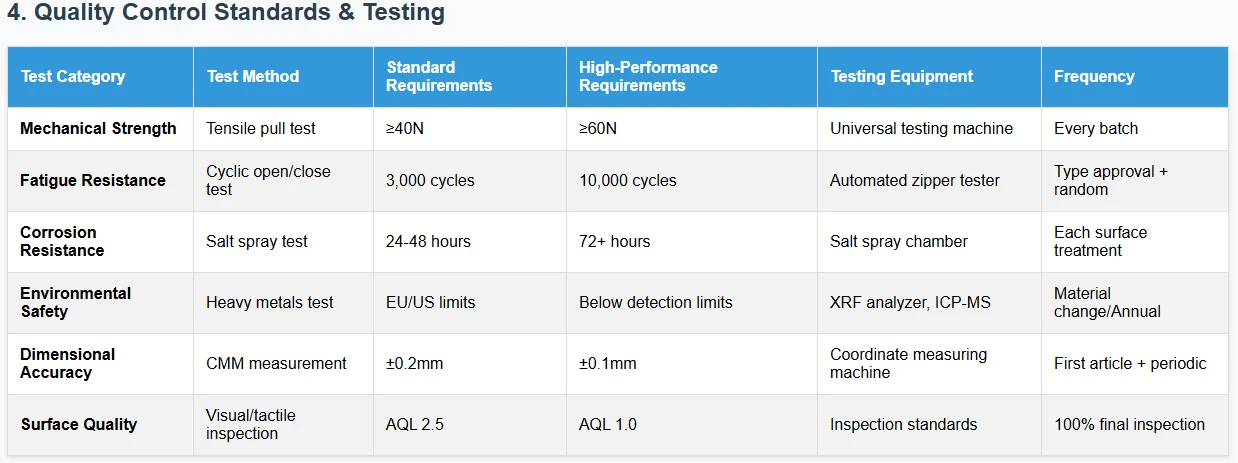

Zipper Puller Installation and Replacement Guide For Brand Buyers

What's the proper process for zipper puller replacement8 and installation to ensure reliable performance?

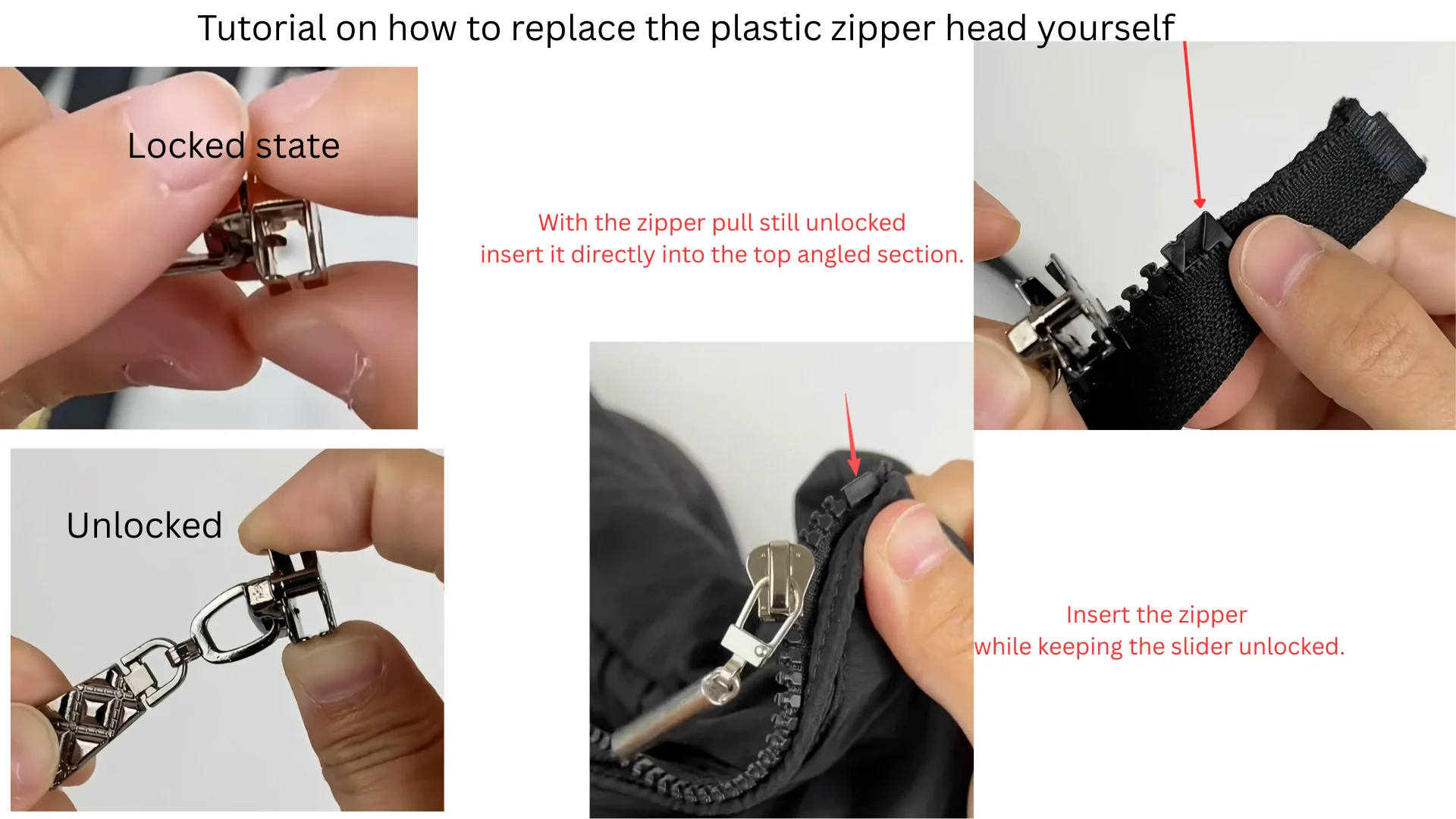

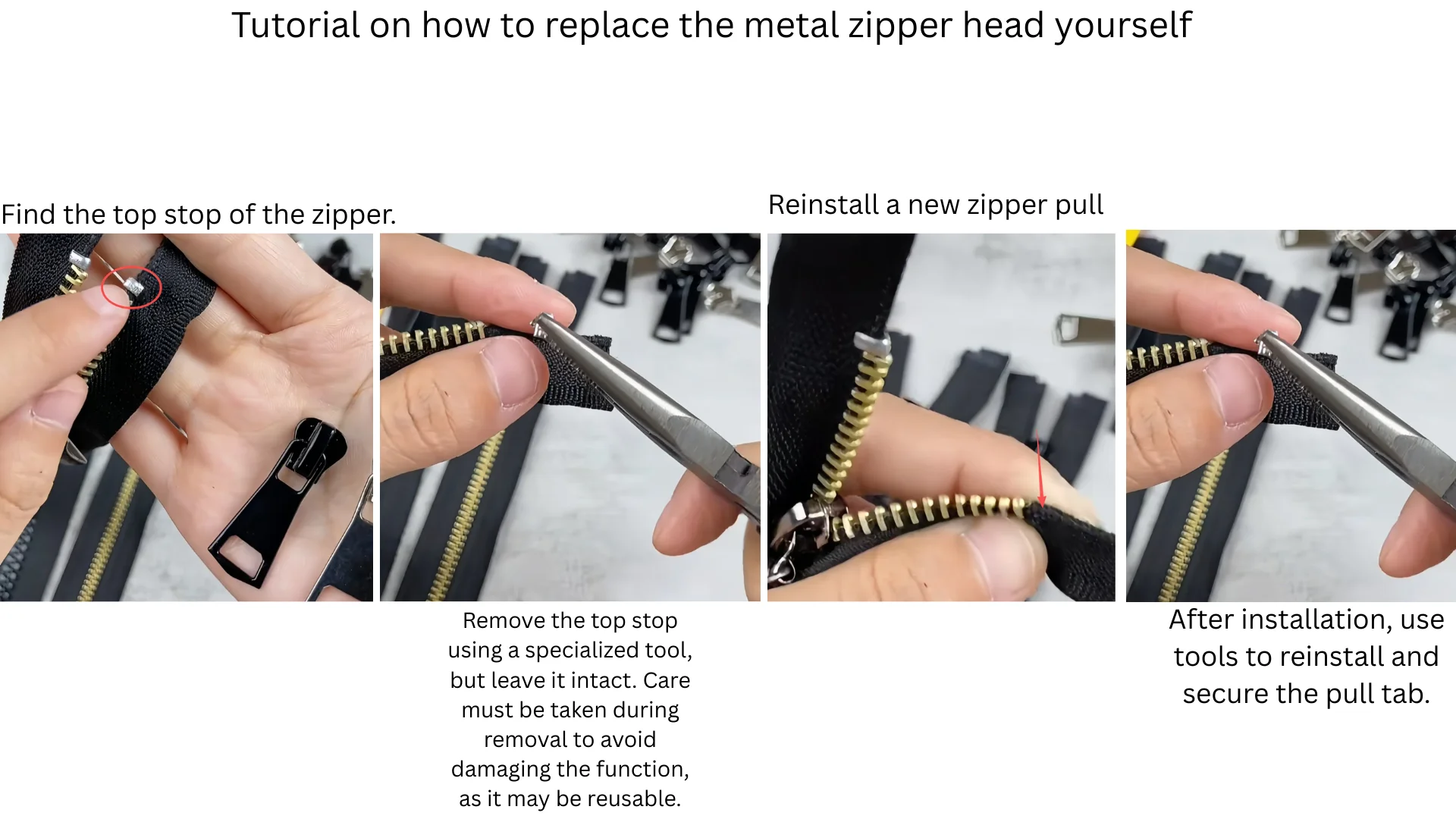

Zipper puller replacement involves removing the old puller from the slider, selecting a compatible replacement, and securely attaching it using appropriate tools and techniques for your specific zipper type.

Through my experience helping clients with zipper puller installation9 issues, I've developed a systematic approach that prevents common mistakes. The process varies depending on your zipper type and puller design, but the principles remain consistent.

Through my experience helping clients with zipper puller installation9 issues, I've developed a systematic approach that prevents common mistakes. The process varies depending on your zipper type and puller design, but the principles remain consistent.

First, assess your current setup. Remove the old puller carefully - some snap off, others require gentle prying or cutting. I always keep samples of removed pullers to ensure exact replacements. The slider connection point is crucial - it must accommodate the new puller's attachment mechanism.

For replacement, timing matters. If you're dealing with production batches, it's often more efficient to replace pullers before final assembly. I've worked with manufacturers who switched to more reliable pullers mid-production, and the earlier in the process, the easier the change.

Quality control becomes essential during installation. At Holyn Textile, we perform immersion tests on completed installations, comparing samples in clean water versus salt water solutions over 24 hours. This reveals potential issues with the attachment point or internal cavities that might retain moisture and cause corrosion.

The most common mistake I see is forcing incompatible pullers onto sliders. This damages both components and leads to premature failure. Always verify compatibility before installation, and consider the user experience - a difficult-to-operate zipper reflects poorly on your brand.

Custom Zipper Puller Design and Manufacturing

How can custom zipper puller design10 elevate your brand while meeting specific functional requirements?

Custom zipper puller development involves design consultation, material selection, prototyping, tooling creation, and production setup to create unique pulls that reflect your brand identity while maintaining functionality.

Creating custom zipper pullers has become one of my favorite collaborations with clients. Each project tells a unique story. Recently, I worked with a sustainable fashion brand that wanted pulls made from recycled ocean plastic. The technical challenges were significant, but the result perfectly embodied their environmental message.

Creating custom zipper pullers has become one of my favorite collaborations with clients. Each project tells a unique story. Recently, I worked with a sustainable fashion brand that wanted pulls made from recycled ocean plastic. The technical challenges were significant, but the result perfectly embodied their environmental message.

The design process starts with understanding your brand and user needs. I always ask clients about their target audience, usage scenarios, and brand personality. A luxury leather goods company needs different solutions than a children's outdoor gear manufacturer. We consider ergonomics, aesthetics, and functionality together.

Material selection for custom pulls requires balancing multiple factors. Environmental considerations increasingly influence choices - many clients now request eco-friendly options even if they cost more. I guide clients through trade-offs between sustainability, performance, and cost.

Prototyping reveals issues that drawings can't capture. I insist on physical samples before committing to tooling because the feel and function often differ from expectations. We test prototypes extensively, including durability testing and user feedback sessions.

Manufacturing setup involves creating specialized tooling and establishing quality control procedures. Minimum order quantities for custom pulls are typically higher than standard options, but the brand differentiation often justifies the investment. I work with clients to plan orders that make economic sense while meeting their launch timelines.

Where to Custom Quality Zipper Pullers Online?

What should you look for when choosing where to buy zipper puller components from online suppliers?

To buy zipper puller components online, research zipper puller supplier credentials, verify quality certifications, request samples, compare pricing structures, and evaluate communication and service capabilities.

Finding reliable suppliers online requires careful evaluation. I've seen too many clients burned by suppliers who looked good on paper but failed to deliver quality or service. At Holyn Textile, we've built our reputation by being transparent about our capabilities and limitations.

Finding reliable suppliers online requires careful evaluation. I've seen too many clients burned by suppliers who looked good on paper but failed to deliver quality or service. At Holyn Textile, we've built our reputation by being transparent about our capabilities and limitations.

Start with supplier verification. Look for business licenses, quality certifications, and factory audits. I always recommend video calls to see actual facilities and meet your contact person. Communication quality during initial inquiries often predicts future service levels.

Sample evaluation is crucial. A reputable supplier will provide samples readily and stand behind their quality. We perform extensive testing on samples, including the salt water immersion tests I mentioned earlier. The sample quality should match production quality exactly.

Consider the complete service package. Beyond just selling pulls, what support do they offer? We help clients with design consultation, quality control planning, and logistics optimization. Some suppliers focus purely on price, but the hidden costs of poor service and quality issues often outweigh initial savings.

Evaluate their client portfolio and ask for references. Established suppliers should have long-term relationships with reputable brands. We're proud of our diverse client base and the repeat business we earn through consistent performance.

Finally, consider location and logistics. While price matters, factor in shipping costs, lead times, and potential delays. We help clients choose transportation methods that balance cost and reliability, sometimes recommending tax-optimized shipping routes that reduce total costs.

Common Zipper Puller Problems and Solutions

What are the most frequent zipper puller problems you'll encounter, and how can you prevent or fix them?

Common zipper puller problems include broken puller handles, detached pulls, stuck operation, and corrosion damage. Most issues stem from material quality, design flaws, or environmental factors affecting zipper hardware performance.

In my experience, zipper puller repair requests usually fall into predictable categories. Understanding these patterns helps prevent problems and guides better initial selections. The most common issue I encounter is broken zipper puller handles, typically caused by material fatigue or impact damage.

In my experience, zipper puller repair requests usually fall into predictable categories. Understanding these patterns helps prevent problems and guides better initial selections. The most common issue I encounter is broken zipper puller handles, typically caused by material fatigue or impact damage.

Detached pulls are another frequent problem, often resulting from inadequate attachment mechanisms or excessive force application. I've learned that user educationis as important as quality hardware - customers need to understand proper zipper operation to prevent damage.

Stuck or difficult operation usually indicates contamination, wear, or misalignment issues. Environmental factors play a huge role here. I remember a client whose outdoor gear zippers seized up in sandy conditions. We redesigned the pulls with better sealing and self-cleaning features.

Corrosion problems are especially common with metal pulls in marine or humid environments. This is why we developed our rigorous testing protocols. Prevention is always better than replacement, so we focus on proper material selection and protective finishes.

For repairs, the approach depends on the specific issue and zipper type. Sometimes replacement is the only option, but often simple adjustments or cleaning can restore functionality. I always provide clients with troubleshooting guides and recommend preventive maintenance schedules11 for critical applications.

The key is designing robustness into the original specification rather than hoping problems won't occur. Quality zipper hardware costs more initially but saves money through reduced warranty claims and customer satisfaction issues.

Conclusion

Choosing the right zipper puller involves understanding your specific needs, material options, and supplier capabilities for long-term success.

Ready to find the perfect zipper puller solution for your project? Contact Holyn Textile today for expert consultation and quality fastener components.

Contact Information:

- Website: holyntextile.com

- Email: [email protected]

- Slogan: High Links High Standard

Get personalized recommendations from our experienced team of fastener specialists. We provide comprehensive solutions from design consultation to quality assurance, ensuring your zipper hardware meets both functional and aesthetic requirements.

Understanding the role of a zipper puller can enhance your knowledge of zipper mechanics and improve your projects. ↩

Learning about zipper hardware basics can save you time and money in your projects. ↩

Exploring various types of zipper pullers helps you choose the right one for your specific needs. ↩

Integrated designs can enhance aesthetics; knowing their features can elevate your product design. ↩

Production volume affects your options; knowing this can help in planning your manufacturing. ↩

Plastic zipper pullers are lightweight and cost-effective; exploring them can benefit your designs. ↩

Exploring eco-friendly materials can align your products with sustainable practices. ↩

Knowing the replacement process ensures reliable performance and extends the life of your zippers. ↩

Proper installation is crucial for functionality; knowing the steps can enhance your assembly process. ↩

Custom designs can reflect brand identity; exploring this can enhance your product appeal. ↩

Implementing a preventive maintenance schedule can help maintain zipper functionality and avoid costly repairs. ↩