What Were the Key Milestones in Zipper Development Throughout History?

Zipper development followed distinct phases, each building on previous innovations while introducing new materials and manufacturing techniques that expanded applications across industries.

**Key milestones include the 1920s-30s adoption in children's and men's clothing, 1951 nylon zipper introduction, 1956 waterproof military zippers,

1958 NASA pressure suit applications1, and 1961 resin injection molding technology

The 1920s and 1930s marked zippers' first widespread adoption in children's and men's clothing . During this period, zipper ends remained fixed together until manufacturers developed separating versions for jacket use. This seemingly simple modification required new engineering approaches to maintain strength while allowing complete separatn.

The 1920s and 1930s marked zippers' first widespread adoption in children's and men's clothing . During this period, zipper ends remained fixed together until manufacturers developed separating versions for jacket use. This seemingly simple modification required new engineering approaches to maintain strength while allowing complete separatn.

Material science drove the next major advancement. Nylon zippers appeared in 1951, opening new possibilities for lighter, more flexible applications [6]. This development coincided with the broader synthetic materials revolution that transformed manufacturing across industries.

Military applications pushed zipper technology in specialized directions. In 1956, British designers created waterproof zippers for moisture-sensitive military equipment storage [3]. These designs used polyethylene-reinforced fiber sheets wrapped around each tooth row [3]. When closed, opposing plastic sheets formed double seals that kept water out completely.

NASA adopted zipper technology in 1958 for high-altitude pressure suits and early space suits [3]. These applications required zippers that maintained air pressure in vacuum conditions. The space program used zippers extending from helmet neck rings to crotch areas, allowing astronauts to dress easily [3]. Mercury and Gemini programs used these pressure zippers, with improved versions developed for Apollo missions [3].

| Year | Innovation | Application | Impact |

|---|---|---|---|

| 1920s-30s | Separating end design | Jackets and coats | Mass adoption in clothing |

| 1951 | Nylon material | Lightweight applications | Expanded design possibilities |

| 1956 | Waterproof sealing | Military equipment | Specialized protection |

| 1958 | Pressure sealing | Space suits | Life-critical applications |

| 1961 | Resin injection molding | Mass production | Cost reduction and variety |

The 1961 introduction of The 1961 introduction of resin zipper injection molding machines2 revolutionized production efficiency . This technology enabled mass production of diverse zipper types, specifications, colors, and functions that served military, civilian, agricultural, medical, aerospace, and aviation applications .

This technology enabled mass production of diverse zipper types, specifications, colors, and functions that served military, civilian, agricultural, medical, aerospace, and aviation applications .

How Did Zippers Transform Fashion and Industrial Applications?

Zippers evolved from practical fasteners into cultural symbols while simultaneously enabling new industrial applications that were previously impossible with traditional fastening methods.

Zippers transformed fashion by enabling new garment designs and becoming cultural symbols, from 1930s "latest tailoring concepts" to 1950s rebellion symbols, while industrial applications expanded into aerospace, military, and specialized equipment requiring reliable sealing.

The fashion revolution began when Esquire magazine featured zippers on men's trousers in the late 1930s, calling them the "latest men's tailoring concept" [3]. This endorsement shifted zippers from functional necessity to fashion statement. The convenience factor appealed to busy modern lifestyles where quick dressing mattered more than traditional formality.

The fashion revolution began when Esquire magazine featured zippers on men's trousers in the late 1930s, calling them the "latest men's tailoring concept" [3]. This endorsement shifted zippers from functional necessity to fashion statement. The convenience factor appealed to busy modern lifestyles where quick dressing mattered more than traditional formality.

Post-World War II culture transformed zippers into rebellion symbols. Hollywood used multi-zipper motorcycle jackets in "The Wild One," where Marlon Brando's character represented youthful defiance [3]. Suddenly, zippers symbolized rough, impulsive culture and sexual liberation [3]. This association continued through the 1970s when The Rolling Stones' "Sticky Fingers" album featured working front zippers on jeans [3].

Industrial applications expanded beyond anyone's original imagination. Waterproof zippers protected sensitive military equipment from humidity damage [3]. Chemical-resistant zippers allowed factory workers to handle dangerous substances safely [4]. Firefighters used fire-resistant zippers that maintained integrity under extreme heat [4].

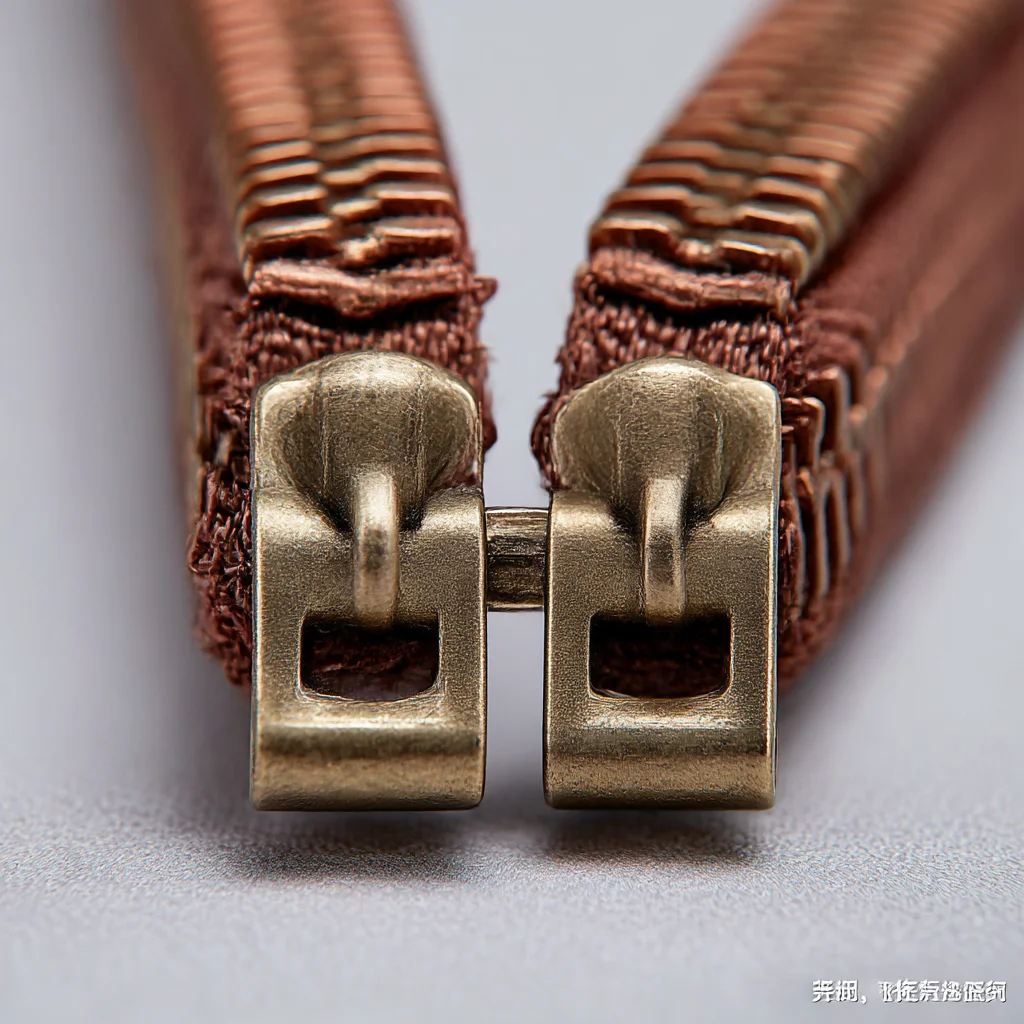

The aerospace industry pushed zipper technology to its limits. Early space suits relied on pressure zippers with dual brass components that compressed rubber gaskets when pressurized [4]. These systems worked reliably for short-term missions but required frequent retesting throughout production and flight test cycles [4]. Copper in brass zippers chemically reacted with rubber gaskets, causing rapid aging [4]. Modern space suits abandoned zippers for hard seals using metal components that compress O-rings [4].

Scuba diving and military applications still use waterproof sealed zippers despite NASA's abandonment of zipper technology [4]. These specialized applications require the flexibility and lightweight properties that only zippers provide, even with their maintenance requirements.

What Manufacturing Innovations Shaped Zipper Production Over Time?

Manufacturing innovations transformed zippers from expensive, hand-crafted items into affordable mass-produced components, with each technological leap enabling new applications and market expansion.

Manufacturing evolved from Sundback's 1917 "S-L" scrapless machine producing hundreds of feet daily to 1961 injection molding systems enabling continuous production of diverse zipper types with improved efficiency and reduced costs.

Evolution of zipper manufacturing technology[^3]

---[^3]: Explore the latest innovations in zipper manufacturing technology to understand how they enhance durability and functionality.")

Sundback's original "S-L" manufacturing machine represented the first major production breakthrough [5]. This device automated the entire tooth-cutting and assembly process, starting with Y-shaped wire and ending with finished zipper tape. The machine's ability to produce several hundred feet daily during 1917 seemed revolutionary compared to hand-assembly methods [5].

Evolution of zipper manufacturing technology[^3]

---[^3]: Explore the latest innovations in zipper manufacturing technology to understand how they enhance durability and functionality.")

Sundback's original "S-L" manufacturing machine represented the first major production breakthrough [5]. This device automated the entire tooth-cutting and assembly process, starting with Y-shaped wire and ending with finished zipper tape. The machine's ability to produce several hundred feet daily during 1917 seemed revolutionary compared to hand-assembly methods [5].

Global technology transfer accelerated manufacturing development. Switzerland, Germany, Japan, and China established production facilities as zipper technology spread worldwide [6]. Japan's "Yoshida Industrial Co." imported automatic tooth machines in 1950, marking Japan's transition into mechanized production [6]. This represented Japan's zipper industry foundation moment.

China's zipper journey began in 1930 when Japanese manufacturers introduced the technology to Shanghai [6]. Initial production relied on hand processing methods [6]. By 1958, Chinese manufacturers transitioned to semi-mechanical processing [6]. The late 1970s brought new technology and equipment imports that continuously improved Chinese zipper production capabilities [6].

Material innovations drove manufacturing changes. Metal zippers dominated early production, but nylon and resin materials required completely different manufacturing approaches [6]. Injection molding technology, introduced in 1961, revolutionized resin zipper production by enabling continuous molding processes [6].

| Era | Manufacturing Method | Daily Output | Key Innovation |

|---|---|---|---|

| 1917 | S-L scrapless machine | Hundreds of feet | Automated tooth cutting |

| 1950s | Semi-mechanical processing | Increased volume | Imported machinery |

| 1961 | Injection molding | Mass production | Continuous molding |

| 1970s+ | Advanced automation | Industrial scale | Computer-controlled systems |

Modern manufacturing incorporates computer-controlled systems that monitor tooth alignment, tension control, and quality parameters in real-time. These systems produce thousands of feet per hour while maintaining consistency that hand production could never achieve. The evolution from Sundback's hundreds of feet daily to modern industrial-scale production represents a thousand-fold improvement in manufacturing efficiency.

Explore this link to understand how NASA pressure suits have evolved and their critical role in space exploration, and 1961 resin injection molding technology.** ↩

Discover how resin zipper injection molding machines transformed manufacturing processes and increased production efficiency across various industries. ↩