I've worked in the garment accessories industry for over a decade now. During this time, I've visited countless manufacturing facilities1 and worked closely with suppliers across China. One question I get asked frequently is about zipper sliders2. How are they made? What goes into producing these small but essential components?

Today, I want to share everything I've learned about zipper slider manufacturing. This guide covers the complete process from raw materials to finished products. I'll also share insights from my experience working with manufacturers and the real costs involved.

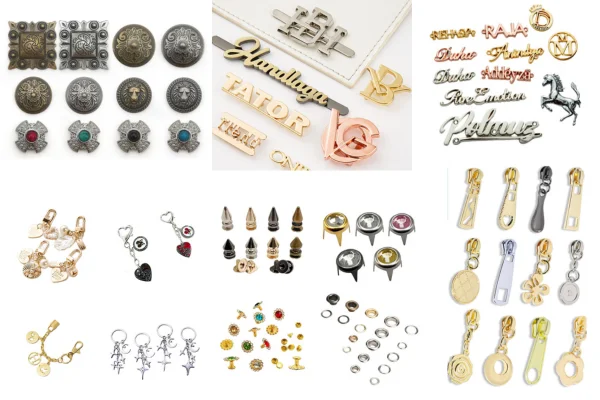

Understanding Zipper Sliders: Types and Functions

A zipper slider is the moving component that opens and closes the zipper. It rides along the zipper chain and joins or separates the teeth. Without a properly functioning slider, even the best zipper becomes useless.

In my years working with suppliers, I've encountered several main types of sliders. Auto-lock sliders are the most common. They have an internal locking mechanism that prevents the slider from moving on its own. Pin-lock sliders require manual pressure to stay closed. Non-lock sliders move freely along the chain.

The choice of slider type depends on the application. I've seen auto-lock sliders3 used extensively in luggage and outdoor gear. Pin-lock types work well for jackets where you want easy operation. Non-lock sliders are common in purses and decorative applications.

Different industries have specific requirements for slider performance4. In automotive applications, I've worked with suppliers who produce sliders that must withstand temperature extremes. Marine applications need superior corrosion resistance. Fashion brands often prioritize appearance and smooth operation. Understanding these requirements helps manufacturers choose the right materials and processes.

The slider's internal mechanism is crucial for proper function. Spring-loaded systems provide the tension needed for auto-lock operation. The geometry of internal surfaces determines how smoothly the slider moves along the teeth. Even small variations in these dimensions can affect performance significantly.

Materials Used in Zipper Slider Manufacturing

Material selection is one of the most critical decisions in slider manufacturing. I've worked with suppliers who use various materials depending on the application and budget requirements.

Zinc Alloy - The Industry Standard

Zinc alloy dominates the slider manufacturing industry. Most of the suppliers I work with use zinc alloy5 ZA-3 or ZA-5 as their primary material. These alloys offer excellent casting properties and good corrosion resistance.

The die casting process6 works particularly well with zinc alloy5. The material flows smoothly into complex mold geometries. It also has a relatively low melting point, which reduces energy costs during production. I've seen manufacturers achieve very tight tolerances with zinc alloy5 components.

Zinc alloy sliders provide good strength for most applications. They handle normal zipper operation well and resist wear over thousands of cycles. The material also takes surface treatment7s well, allowing for various finishes and colors.

Brass for Premium Applications

Brass sliders represent the premium end of the market. I work with several suppliers who specialize in brass components for high-end fashion brands and luxury goods. Brass offers superior durability and an attractive natural appearance.

The manufacturing process for brass sliders8 requires more specialized equipment. Brass has a higher melting point than zinc alloy5, which increases production costs. However, the resulting sliders have excellent corrosion resistance and can last for decades with proper care.

Many fashion designers prefer brass sliders8 for their aesthetic qualities. The material can be polished to a high shine or given various patina finishes. I've seen brass sliders8 used on premium leather goods where appearance is just as important as function.

Plastic and Nylon Alternatives

Plastic sliders serve specific market segments where metal components aren't suitable. I work with suppliers who produce injection-molded plastic sliders9 for applications requiring lighter weight or non-metallic construction.

Nylon and other engineering plastics can provide good durability while keeping costs low. These materials work well for children's clothing, swimwear, and other applications where metal might cause problems. The injection molding process allows for complex shapes and integrated features.

However, plastic sliders9 have limitations. They generally don't provide the same smooth operation as metal components. Temperature sensitivity can also be an issue in extreme environments. I always discuss these trade-offs with customers when plastic sliders9 are being considered.

Specialty Materials (Aluminum, Stainless Steel)

Some applications require specialty materials. I've worked with suppliers producing aluminum sliders10 for aerospace applications where weight is critical. Stainless steel sliders serve marine and medical applications where corrosion resistance is paramount.

These specialty materials require modified manufacturing processes. Aluminum has different casting characteristics than zinc alloy5. Stainless steel may require machining rather than casting for some components. The additional complexity increases costs but provides superior performance in demanding applications.

Complete Zipper Slider Manufacturing Process

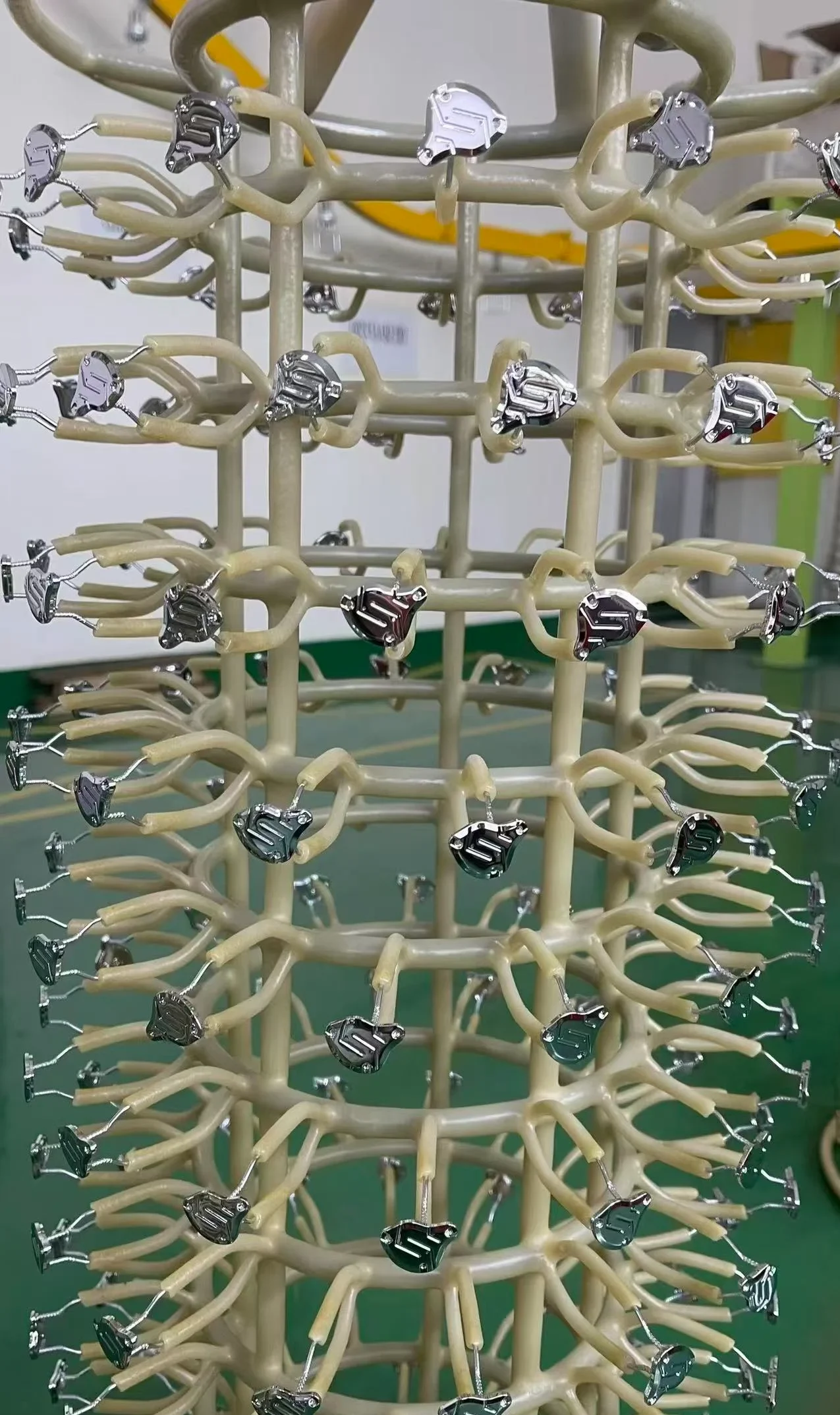

The slider manufacturing process involves several precise steps. I've spent countless hours in production facilities observing these operations. Each step must be carefully controlled to ensure consistent quality.

Step 1: Die Casting Process

Die casting forms the foundation of metal slider production. The process begins with mold preparation. Operators clean the mold cavities and apply release agents to prevent sticking. The mold halves are then securely clamped together.

Molten metal gets injected into the mold under high pressure. I've watched operators monitor injection parameters carefully. Pressure, temperature, and timing all affect the final part quality. Too little pressure creates incomplete filling. Too much pressure can damage the mold or create flash.

The cooling phase is critical for dimensional accuracy. Operators control cooling rates to minimize warpage and internal stress. Most facilities use water-cooled molds to maintain consistent temperatures. Cycle times typically range from 30 seconds to 2 minutes depending on part size.

Demolding requires careful handling to avoid damage. Automated systems use robotic arms to extract parts consistently. Manual operations rely on skilled operators to maintain production rates. I've seen facilities produce thousands of slider bodies per day using efficient die casting setups.

Quality checks happen immediately after demolding. Operators inspect parts for surface defects, dimensional accuracy, and completeness. Defective parts get recycled back into the melting furnace. This immediate feedback helps maintain consistent quality throughout production runs.

Step 2: Precision Machining and Finishing

Die cast parts typically require additional machining to achieve final specifications. CNC machining operations create precise bearing surfaces and internal geometries. I've worked with suppliers who invest heavily in high-precision machining11 equipment.

Surface grinding removes casting marks and achieves smooth finishes. This step is particularly important for surfaces that contact the zipper teeth. Rough surfaces cause excessive wear and poor operation. Skilled machinists monitor surface finish measurements continuously.

Polishing operations prepare parts for surface treatment7s. Different grit sequences achieve the desired surface texture. Some applications require mirror-like finishes, while others need controlled roughness for coating adhesion. I've seen operators spend considerable time perfecting polishing techniques.

Dimensional accuracy control happens throughout machining operations. Coordinate measuring machines verify critical dimensions on sample parts. Statistical process control helps identify trends before problems occur. Tight tolerances are essential for proper slider function.

Step 3: Assembly and Component Integration

Slider assembly brings together multiple components into a functional unit. Spring mechanism installation requires precise positioning and tension control. I've watched skilled assemblers install hundreds of springs per hour while maintaining consistent quality.

Pull tab attachment involves several methods depending on design requirements. Some tabs are pressed onto the slider body using hydraulic equipment. Others use mechanical fasteners or welding processes. The attachment must withstand significant pulling forces during normal use.

Internal component assembly includes installing lock mechanisms and bearing surfaces. These components must be properly aligned and lubricated for smooth operation. I've seen assembly workers use specialized fixtures to ensure consistent positioning.

Quality testing happens after each assembly step. Operators check spring tension, lock function, and overall operation. Defective assemblies get disassembled and components recycled where possible. This testing catches problems before expensive finishing operations.

Step 4: Surface Treatment and Plating

Electroplating provides corrosion protection and aesthetic appeal. The process begins with thorough cleaning to remove oils and surface contamination. Parts then go through a series of chemical baths to prepare the surface for plating.

Nickel plating serves as a base layer for most applications. This provides good corrosion resistance and a smooth surface for subsequent coatings. Chrome plating adds hardness and a bright finish for premium applications. I've worked with plating shops that maintain strict control over bath chemistry and current density.

Powder coating offers an alternative to wet plating processes. Parts are electrostatically charged and coated with powder materials. Baking in ovens cures the coating into a durable finish. This process works well for plastic components and provides excellent color consistency.

Anti-corrosion treatments extend product life in harsh environments. Salt spray testing verifies coating durability before approving production lots. I've seen manufacturers develop specialized coatings for marine and automotive applications that exceed standard industry requirements.

Quality Control and Testing Standards

Quality control systems ensure consistent product performance. I've worked with suppliers who invest heavily in testing equipment and procedures. These investments pay off through reduced warranty claims and improved customer satisfaction.

Dimensional Inspection Procedures

Precision measurement tools12 verify that parts meet specifications. Coordinate measuring machines13 check critical dimensions on sample parts from each production lot. Go/no-go gauges provide quick checks for high-volume inspection. Skilled inspectors understand which dimensions affect function most critically.

Statistical process control14 tracks measurement data over time. Control charts help identify trends before they cause quality problems. I've seen facilities use this data to optimize machining parameters and reduce variation. Regular calibration ensures measurement accuracy.

Surface finish measurements15 verify that plating and coating operations meet requirements. Roughness meters and visual standards guide inspectors in evaluating part quality. Consistent surface preparation is essential for coating adhesion and appearance.

Functional Testing Methods

Pull tests16 verify that sliders can withstand specified loads without failure. Testing machines apply controlled forces while measuring displacement. I've watched technicians perform thousands of these tests to establish design limits and verify production quality.

Cycle testing17 simulates normal zipper operation over extended periods. Automated machines open and close zippers repeatedly while monitoring for wear or failure. These tests help predict service life and identify potential design improvements.

Environmental testing18 exposes parts to temperature, humidity, and corrosive conditions. Salt spray chambers simulate marine environments. Temperature cycling tests verify performance over expected operating ranges. I've seen manufacturers develop specialized test protocols for specific customer applications.

Durability and Strength Testing

Fatigue testing19 determines how long sliders will last under repeated use. Testing machines cycle parts through millions of operations while monitoring for crack initiation or failure. This data helps establish warranty periods and maintenance recommendations.

Impact testing verifies that sliders can survive accidental drops or rough handling. Drop towers and pendulum impact machines apply controlled forces to test specimens. Results help optimize material selection and design details.

Wear testing evaluates how surfaces hold up under sliding contact. Specialized machines simulate zipper operation while measuring wear rates and surface changes. Lubrication studies determine optimal materials and application methods.

Industry Standards and Certifications

ISO 9001 certification20 demonstrates commitment to quality management systems. I work primarily with suppliers who maintain this certification. The documentation and process control requirements help ensure consistent quality across all production activities.

OEKO-TEX standards21 address chemical safety in textile applications. Zippers used in clothing must meet strict limits on harmful substances. Testing laboratories verify compliance with these requirements before products can be sold in many markets.

Customer-specific standards often exceed industry minimums. Automotive suppliers must meet IATF 16949 requirements. Military applications follow MIL-SPEC standards. I help customers understand which standards apply to their specific applications.

Modern Manufacturing Technology and Automation

Automation transforms slider manufacturing22 by improving consistency and reducing costs. I've visited facilities that use robotic systems for material handling, machining, and assembly operations. These investments pay off through higher quality and lower labor costs.

Automated die-casting systems maintain consistent process parameters across production runs. Computer controls monitor temperature, pressure, and timing with precision impossible for manual operations. Real-time adjustments compensate for variations in material properties or ambient conditions.

Robotic handling systems move parts between operations without human contact. This eliminates contamination and handling damage while increasing throughput. I've seen robots equipped with vision systems that can sort parts based on quality criteria.

AI-powered quality inspection23 uses machine learning to identify defects that human inspectors might miss. Camera systems capture high-resolution images of every part. Software algorithms compare these images to learned patterns of acceptable and defective parts. Detection rates often exceed 99% accuracy.

Integration of these technologies creates smart manufacturing systems that can adapt to changing conditions. Predictive maintenance algorithms monitor equipment health and schedule service before failures occur. Production planning software optimizes schedules based on real-time demand and capacity constraints.

Production Specifications and Lead Times

Manufacturing tolerances24 for slider components are typically very tight. Critical dimensions like internal clearances must be held to ±0.02mm or better. I work with suppliers who use precision tooling and measurement systems to achieve these requirements consistently.

Production capacity varies significantly between facilities. Small shops might produce 10,000 pieces per day while large automated facilities can exceed 200,000 pieces daily. Multiple production lines allow for flexibility in handling different product types and rush orders.

Typical order quantities range from 10,000 to 500,000 pieces depending on application. Fashion accessories often require smaller batches with frequent design changes. Industrial applications typically involve larger quantities with stable specifications over longer periods.

Lead times depend on several factors including mold availability, material procurement, and production schedules. Standard products using existing tooling typically require 15-25 days. Custom designs requiring new molds add 30-45 days for tooling development and approval.

Cost Factors in Zipper Slider Manufacturing

Material costs25 represent the largest component of slider manufacturing expenses. Zinc alloy prices fluctuate based on global commodity markets. I help customers understand how these variations affect product pricing and plan accordingly for budget purposes.

Labor costs vary significantly between regions and levels of automation. Highly automated facilities can reduce labor content to 15-20% of total costs. Traditional manual operations might see labor representing 25-30% of expenses. Investment in automation equipment must be balanced against labor savings.

Volume pricing structures reflect economies of scale in manufacturing. Setup costs for tooling changes are spread across production quantities. Raw material purchasing power increases with order volume. I've seen unit costs drop by 20-30% when order quantities increase from 50,000 to 500,000 pieces.

Quality costs include inspection, testing, and rework activities. Prevention costs are typically much lower than correction costs after problems are discovered. I work with suppliers who invest heavily in process control to minimize quality-related expenses.

Through my research, I've found three major cost misconceptions that buyers often have: Misconception 1: Focusing Only on Unit Price, Ignoring Total Cost of Ownership I tracked a brand's supplier switching and found that Supplier A with 0.8 RMB unit price had 8% scrap rate and 3% customer complaint rate, resulting in actual cost of 0.89 yuan. Supplier B with 1.2 yuan unit price had only 1% scrap rate and 0.2% complaint rate, with actual cost of 1.21 yuan. The total cost calculation must include quality factors. Misconception 2: Ignoring the Critical Point of Batch Effect Based on cost analysis of 15 factories, I found significant cost reductions at key volume thresholds. Orders of 50,000 units achieve 15-20% cost reduction due to decreased mold amortization. At 200,000 units, dedicated production lines start, reducing costs by 8-12%. Orders of 1,000,000 units provide 5-8% additional savings through raw material bargaining power. Misconception 3: Underestimating Quality Cost Amplification Quality costs have a multiplying effect throughout the supply chain. Poor quality sliders can cause entire garment rejections, warranty claims, and brand damage. Prevention costs are always lower than correction costs after problems are discovered.

Frequently Asked Questions

How long does it take to manufacture zipper sliders?

Standard slider production[^26] typically takes 15-25 days from order placement to shipping. This includes material procurement[^27], production scheduling, manufacturing operations, quality testing[^28], and packaging. Custom designs requiring new tooling add 4-6 weeks for mold development and approval samples.

Rush orders can sometimes be accommodated if raw materials are available and production capacity exists. However, rushing production often increases costs and may compromise quality controls. I always recommend planning ahead to allow normal production schedules.

What determines zipper slider quality?

Material selection has the biggest impact on slider quality and longevity. Premium alloys and proper heat treatment create durable components that resist wear and corrosion. Surface treatments must be properly applied to provide long-term protection.

Manufacturing precision determines how smoothly sliders operate. Tight tolerances on internal surfaces ensure proper zipper teeth engagement. Assembly quality affects spring tension and lock mechanism function. Consistent processes produce reliable results batch after batch.

Can zipper sliders be customized?

Yes, sliders can be extensively customized for specific applications. Shape, size, color, and decorative elements can all be modified. Custom pull tabs with logos or special textures are common requests. I work with customers to develop unique designs that meet their functional and aesthetic requirements.

Customization typically requires new tooling which adds cost and lead time. Minimum quantities are usually higher for custom designs[^29] to justify tooling investments. However, the resulting product differentiation often provides significant marketing advantages.

What's the difference between metal and plastic sliders[^30]?

What's the difference between metal and plastic sliders[^30]?

Metal sliders generally provide smoother operation and longer service life. They handle higher loads and resist wear better than plastic alternatives. Surface treatments on metal components offer superior corrosion protection and appearance retention.

Plastic sliders are lighter weight and cost less to produce. They work well for applications where metal detection is a concern

How do manufacturers ensure consistent quality?

Statistical process control26 systems track key parameters throughout production. Control charts identify trends before they cause quality problems. I work with suppliers who use this data to optimize processes and reduce variation. Real-time monitoring catches deviations immediately.

Incoming material inspection verifies that raw materials meet specifications. Chemical analysis confirms alloy composition within tight tolerances. Dimensional checks ensure consistent feedstock properties. Contamination testing prevents quality problems from starting in the production process.

In-process monitoring catches problems early when corrections are still possible. Temperature monitoring during die casting prevents defective parts. Dimensional checks during machining identify tool wear before it affects quality. Assembly torque monitoring ensures consistent spring tension across all units.

Final inspection uses both automated and manual methods. Vision systems check dimensional accuracy and surface quality with precision impossible for human inspectors. Pull testing verifies strength requirements on statistical samples. Functional testing confirms smooth operation and proper lock engagement.

Supplier audits help maintain quality standards across the entire supply chain. I regularly visit production facilities to observe processes and review quality records. These audits identify potential problems before they affect customer shipments. Continuous improvement programs encourage suggestions for better methods

Training programs ensure that operators understand quality requirements27. Skilled workers recognize quality problems early and know how to correct them. Regular refresher training keeps quality awareness high throughout the organization.

What are typical lead times for custom slider orders?

Custom slider projects typically require 6-8 weeks from initial design approval to first production shipments. This includes tooling design and fabrication, sample production28 and approval, process optimization3, and initial production runs.

Tooling development takes 3-4 weeks for most custom designs. Complex shapes or special features may require additional time for design refinement and testing. I always recommend allowing extra time for unexpected challenges during tooling development4 and debugging.

Sample production and approval add 1-2 weeks to the schedule. Multiple iterations may be needed to achieve desired appearance and function. Rush sample production28 is possible but increases costs significantly and may compromise quality validation.

Process optimization happens during initial production runs. Parameters like injection pressure, cooling time, and assembly sequences need fine-tuning for each new design. This typically takes 3-5 days of production time to achieve stable operation.

Production scheduling depends on facility capacity and material availability. Busy seasons like pre-fashion week periods may extend lead times by 1-2 weeks. I work with customers to plan orders around these capacity constraints when possible.

How has zipper slider technology evolved over time?

The evolution of slider technology traces back to the early pioneers who developed the fundamental concepts we still use today. When Elias Howe first patented his "Automatic, Continuous Clothing Closure" in 1851, the concept was revolutionary but the execution was flawed. The design was difficult to use, prone to rust, and expensive to manufacture.

Whitcomb Judson's improvements in 1891 marked the next major step. His "Clasp Locker or Unlocker for Shoes" introduced the sliding mechanism that gives zippers their name. Though demonstrated at the 1893 Chicago World's Fair, commercial success remained limited due to reliability issues.

The breakthrough came with Gideon Sundback's work from 1908 to 1917. His "separable fastener" design established the tooth-and-groove system that modern sliders still use. Sundback increased tooth density from 4 per inch to 10-11 per inch, creating the smooth operation we expect today.

The name "zipper" itself came from B.F. Goodrich Company's marketing team, who loved the distinctive "zip" sound the fastener made. This onomatopoetic naming captured the essence of the product's quick operation and helped establish brand recognition.

Modern innovations continue pushing slider technology forward. Smart magnetic sliders like Under Armour's Magzip system allow one-handed operation. Specialized applications in aerospace, marine, and chemical industries drive development of new materials and sealing systems.

Conclusion

Zipper slider manufacturing combines traditional metalworking techniques with modern precision manufacturing. The process requires careful control of materials, processes, and quality systems29 to produce reliable components that perform consistently over thousands of operations.

My experience working with manufacturers across China has taught me that quality comes from attention to detail at every step. From raw material selection through final inspection, each decision affects the end product. The best suppliers invest in modern equipment, train their workers well, and maintain rigorous quality systems29.

Cost optimization requires understanding the total cost picture, not just unit prices. Quality problems multiply costs throughout the supply chain. Volume planning affects unit costs significantly. Lead time planning prevents rush charges and quality compromises. Smart buyers focus on total cost of ownership30 rather than just purchase price.

The zipper slider industry continues evolving with new materials, automation technology7, and quality systems29. Manufacturers who invest in these improvements provide better products at competitive prices. As a buyer, working with these progressive suppliers ensures access to the latest capabilities and consistent quality performance.

Understanding the manufacturing process31 helps in making better sourcing decisions. When you know what goes into producing quality sliders, you can evaluate suppliers more effectively and specify requirements that lead to successful outcomes. This knowledge also helps in troubleshooting problems when they occur and working with suppliers to implement improvements.

The historical development from Sundback's early innovations to today's automated production lines shows how far the industry has come. Yet the fundamental principles remain the same - precision manufacturing, quality materials, and careful attention to detail create sliders that serve reliably throughout their service life.

Whether you're sourcing sliders for fashion accessories, industrial applications, or consumer products, the principles remain consistent. Quality materials, precise manufacturing, and rigorous quality control produce sliders that perform reliably throughout their service life. The investment in understanding these processes pays dividends through better supplier relationships and superior end products.

The future of slider manufacturing will likely see continued automation, new materials for specialized applications, and integration with smart textiles32 and wearable technology. However, the core manufacturing principles of precision, quality, and reliability will remain as important as ever. Understanding these fundamentals provides the foundation for success in any zipper slider application.

Explore the advancements in manufacturing facilities that improve zipper slider production efficiency. ↩

Explore the intricacies of zipper sliders, their types, and manufacturing processes to enhance your understanding. ↩

Learn about auto-lock sliders, their advantages, and applications in various industries. ↩

Understand the critical factors that influence the performance of zipper sliders in different applications. ↩

Explore the benefits of zinc alloy in slider production and its impact on durability. ↩

Understand the die casting process and its importance in producing high-quality sliders. ↩

Discover the various surface treatments that enhance the durability and appearance of sliders. ↩

Learn why brass sliders are preferred for high-end applications and their unique properties. ↩

Discover the pros and cons of plastic sliders in various applications. ↩

Find out how aluminum sliders are utilized in aerospace and other specialized applications. ↩

Explore the role of precision machining in achieving the exact specifications for zipper sliders. ↩

Explore this link to understand how precision measurement tools ensure product quality and compliance with specifications. ↩

Learn about the role of coordinate measuring machines in verifying critical dimensions and enhancing manufacturing accuracy. ↩

Discover how statistical process control helps in tracking quality and optimizing production processes. ↩

Find out why surface finish measurements are crucial for ensuring product quality and performance. ↩

Understand the significance of pull tests in verifying the strength and reliability of manufacturing components. ↩

Explore the importance of cycle testing in predicting product lifespan and identifying design improvements. ↩

Learn about environmental testing and its role in ensuring product performance under various conditions. ↩

Discover how fatigue testing helps manufacturers understand the longevity of their products under repeated use. ↩

Explore the benefits of ISO 9001 certification in ensuring quality management and consistency in production. ↩

Learn about OEKO-TEX standards and their importance in ensuring chemical safety in textile products. ↩

Discover the impact of automation on manufacturing efficiency, quality, and cost reduction. ↩

Explore how AI-powered quality inspection enhances defect detection and improves manufacturing accuracy. ↩

Understand the significance of manufacturing tolerances in achieving product quality and performance. ↩

Learn about the various factors that affect material costs and how they impact overall manufacturing expenses. ↩

Discover how statistical process control helps maintain consistent quality in manufacturing. ↩

Explore this link to learn how to implement effective quality management systems that enhance product reliability. ↩

This resource will provide insights into the importance of sample production in achieving desired product quality. ↩

Discover effective strategies for process optimization that can lead to improved production outcomes. ↩

Understanding tooling development is crucial for optimizing production efficiency and reducing lead times. ↩

This link offers a comprehensive overview of quality systems that ensure consistent product performance. ↩

Understanding total cost of ownership helps in making informed purchasing decisions that impact long-term costs. ↩