How Do Airtight Zippers Really Work?

Have you ever wondered how your drysuit keeps you completely dry underwater? The secret lies in specialized airtight zippers that create perfect seals.

Airtight zippers1 use dual-layer sealing technology2 with waterproof and air-tight layers that work together. When closed, they form a complete barrier against both water and air infiltration, making them essential for diving equipment, protective clothing, and waterproof storage.

I have spent years working with clients who need the most reliable sealing solutions. Today, I want to share everything I know about airtight zippers and how they can solve your waterproofing challenges.

I have spent years working with clients who need the most reliable sealing solutions. Today, I want to share everything I know about airtight zippers and how they can solve your waterproofing challenges.

with waterproof and air-tight layers that work together. When closed, they form a complete barrier against both water and air infiltration, making them essential for diving equipment, protective clothing, and waterproof storage.**

What Makes Airtight Zippers Waterproof?

You might think all zippers are the same, but airtight zippers work completely differently from regular ones. They can keep your gear bone dry in the harshest conditions.

Airtight zippers use a double sealing system. The outer waterproof layer blocks liquid while the inner airtight layer prevents air penetration. This dual protection creates an impermeable barrier when the zipper closes.

The waterproof principle works through interlocking teeth that create a sealed chamber. When you close an airtight zipper, the teeth mesh together to form the first barrier. But that's not enough for true air-tightness. The real magic happens with the secondary sealing layer.

The waterproof principle works through interlocking teeth that create a sealed chamber. When you close an airtight zipper, the teeth mesh together to form the first barrier. But that's not enough for true air-tightness. The real magic happens with the secondary sealing layer.

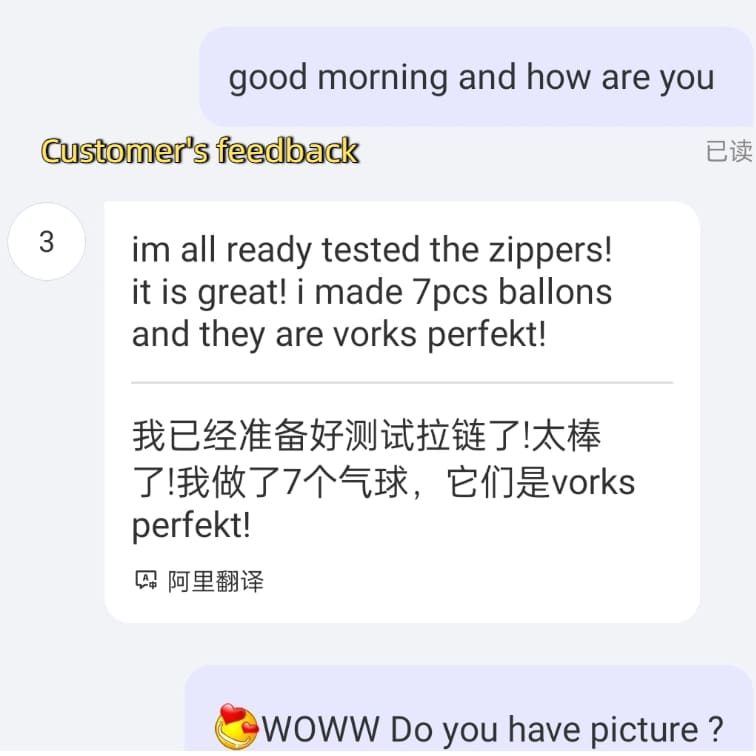

This inner layer uses special polymer materials that compress when the zipper closes. The compression creates a gas-tight seal that prevents even tiny air molecules from passing through. I remember working with a Hungarian client who needed #10 TPU 2-meter closed-end airtight zippers for industrial balloons. The precision required was incredible - even a tiny leak would cause the balloons to fail.

The sealing effectiveness depends on the pressure differential and the quality of the sealing materials. Higher-grade airtight zippers can maintain their seal under significant pressure differences. This makes them perfect for applications like drysuits, where divers rely on complete water exclusion to stay warm and safe underwater.

Which Materials Work Best for Airtight Zippers?

The materials used in airtight zipper construction determine their performance and durability. Not all materials can handle the demands of true air-tight sealing3.

High-strength nylon or plastic forms the waterproof layer4, while specialized polymer coatings or TPU create the airtight seal. These materials must resist water penetration and maintain flexibility under pressure.

The waterproof layer typically uses reinforced nylon fabric or high-grade plastic compounds. These materials need exceptional tear resistance because they face constant stress during opening and closing cycles. I've seen cheap materials fail after just a few uses, which is why we only work with Grade-A suppliers who provide verified compliance certificates.

The waterproof layer typically uses reinforced nylon fabric or high-grade plastic compounds. These materials need exceptional tear resistance because they face constant stress during opening and closing cycles. I've seen cheap materials fail after just a few uses, which is why we only work with Grade-A suppliers who provide verified compliance certificates.

The airtight layer requires even more specialized materials. TPU (Thermoplastic Polyurethane5) has become the gold standard because of its excellent sealing properties and environmental friendliness. Unlike older CR (Chloroprene Rubber) materials, TPU doesn't contain heavy metals and offers better heat welding characteristics.

CR materials6 still have their place, especially in applications requiring maximum gas retention. However, they present environmental concerns due to heavy metal content. The choice between materials often comes down to balancing performance requirements with environmental responsibility. For most applications, TPU provides the best combination of sealing performance and eco-friendliness.

CR materials still have their place, especially in applications requiring maximum gas retention. However, they present environmental concerns due to heavy metal content. The choice between materials often comes down to balancing performance requirements with environmental responsibility. For most applications, TPU provides the best combination of sealing performance and eco-friendliness.

What Types of Airtight Zippers Are Available?

Different applications require different zipper designs. The three main types each offer unique advantages for specific use cases.

Three main types exist: woven nylon airtight zippers1, resin airtight zippers2 (also called AQUASEAL3), and metal airtight zippers4 (like YKK's PROSEAL5). Each type suits different applications and performance requirements.

Woven nylon airtight zippers offer the best balance of flexibility and strength. They work well in clothing applications where the zipper needs to bend and flex with body movement. I often recommend these for drysuit applications6 because they maintain their seal even when the fabric stretches.

Resin airtight zippers, known as AQUASEAL3 zippers, use injection-molded plastic teeth. These provide excellent chemical resistance and work well in harsh environments. They're popular in industrial applications where exposure to chemicals or extreme temperatures is common.

Metal airtight zippers, such as YKK's PROSEAL5 system, offer maximum durability and the strongest seal under high pressure. However, they're less flexible and heavier than other options. These work best in rigid applications like equipment cases or industrial containers.

The manufacturing process for each type requires different expertise. Our zip factory uses specialized equipment for each type, and we maintain dual production lines for critical processes to ensure consistent quality. When selecting the right type, I always consider the application's flexibility requirements, pressure levels, and environmental conditions.

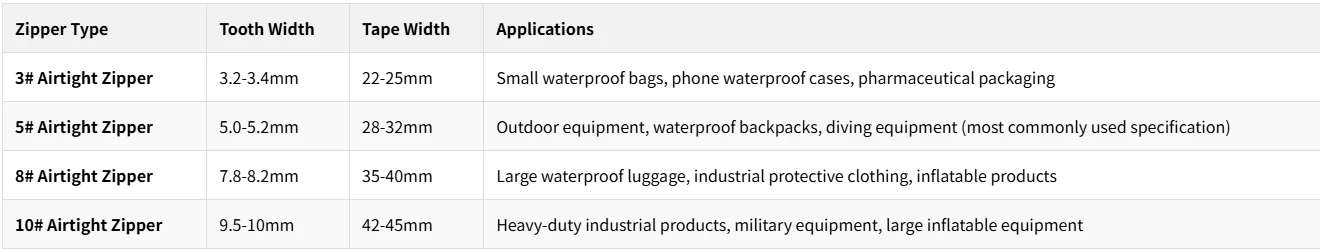

Common Airtight Zipper Specifications

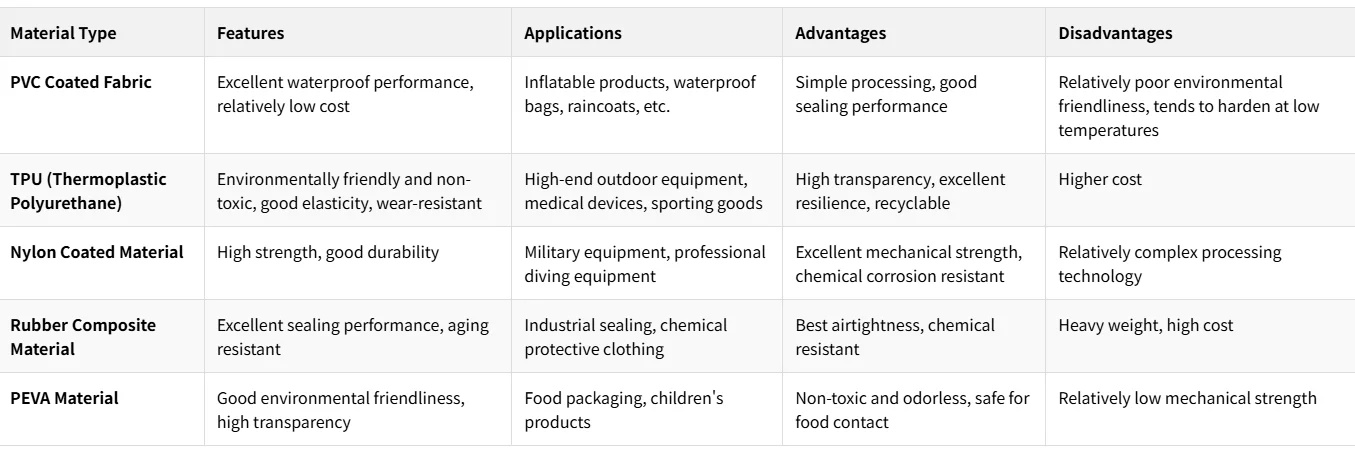

Main Material Types for Airtight Zipper Tapes

FOR MORE INFO ,PLEASE CONTACT US

What Types of Airtight Zippers Are Available?

When selecting airtight zipper tape materials, consider:

Application Environment (temperature, humidity, chemical contact) Performance Requirements (airtightness, durability, flexibility) Cost Budget Environmental Requirements **Processing Compatibility

Where Do You Use Airtight Zippers?

Airtight zippers serve critical functions across many industries. Their ability to create perfect seals makes them essential for safety and performance applications.

Major applications include diving equipment like drysuits and waterproof bags, aerospace components7 requiring pressurization, and protective packaging8 for sensitive items. Each application demands specific performance characteristics.

In diving applications, airtight zippers are literally life-saving components. Drysuit zips must maintain perfect seals at depth while allowing easy operation with gloved hands. I've worked with several diving equipment manufacturers who require zippers that can handle repeated pressure cycles without degradation.

In diving applications, airtight zippers are literally life-saving components. Drysuit zips must maintain perfect seals at depth while allowing easy operation with gloved hands. I've worked with several diving equipment manufacturers who require zippers that can handle repeated pressure cycles without degradation.

The aerospace industry presents unique challenges. Aircraft and spacecraft components need airtight seals that function reliably across extreme temperature ranges and pressure differentials. These applications often require custom zipper solutions with specialized testing and certification.

Protective packaging represents the fastest-growing application area. Airtight zipper pouches protect sensitive electronics, documents, and supplies from moisture and contamination. Medical applications are particularly demanding - I recently supplied airtight zippers for reusable protective equipment that needed to maintain sealing effectiveness9 through multiple sterilization cycles.

Protective packaging represents the fastest-growing application area. Airtight zipper pouches protect sensitive electronics, documents, and supplies from moisture and contamination. Medical applications are particularly demanding - I recently supplied airtight zippers for reusable protective equipment that needed to maintain sealing effectiveness9 through multiple sterilization cycles.

Emergency and military applications also rely heavily on airtight zippers. During the COVID-19 pandemic, we supplied components for reusable protective suits that could be washed and sterilized up to 10 times while maintaining their protective sealing capabilities. This application showed how airtight zipper technology can contribute to both safety and environmental sustainability.

Emergency and military applications also rely heavily on airtight zippers. During the COVID-19 pandemic, we supplied components for reusable protective suits that could be washed and sterilized up to 10 times while maintaining their protective sealing capabilities. This application showed how airtight zipper technology can contribute to both safety and environmental sustainability.

What Breakthrough Technologies Are Emerging?

Innovation in airtight zipper technology continues to advance rapidly. New materials and manufacturing techniques are pushing the boundaries of what's possible.

Recent breakthroughs include improved TPU compounds10 with better UV resistance, self-lubricating sealing systems11, and smart zippers with integrated sensors. These advances improve durability while adding new functionality.

UV resistance has been a major breakthrough area. Traditional airtight zippers degraded quickly under sunlight exposure, leading to seal failure and surface cracking. New TPU formulations with UV stabilizers extend service life significantly, making them suitable for outdoor applications that were previously problematic.

UV resistance has been a major breakthrough area. Traditional airtight zippers degraded quickly under sunlight exposure, leading to seal failure and surface cracking. New TPU formulations with UV stabilizers extend service life significantly, making them suitable for outdoor applications that were previously problematic.

Self-lubricating systems represent another major advance. These zippers incorporate lubricants directly into the sealing materials, reducing the need for external maintenance while improving operational smoothness. This is particularly valuable in applications where regular maintenance is difficult or impossible.

Smart zipper technology is emerging for high-value applications. These systems can monitor seal integrity and alert users to potential failures before they occur. While still expensive, this technology shows promise for critical applications like aerospace and medical equipment.

Manufacturing process improvements have also enabled new capabilities. Advanced heat welding techniques allow for stronger, more precise seals. Our zip factory has invested in new equipment that can produce custom airtight solutions with tolerances that were impossible just a few years ago.

How Should You Properly Use Airtight Zippers?

Proper technique is essential for airtight zipper performance12 and longevity. Wrong usage can quickly destroy even the best zippers.

Always pull smoothly without forcing, accelerate gradually when approaching full closure, and test the seal by gently squeezing the sealed area. Proper maintenance includes regular cleaning and appropriate lubrication.

The most important rule is never force an airtight zipper. These zippers have much higher resistance than regular zippers due to their sealing mechanisms. Forcing them will damage the sealing surfaces and compromise performance permanently.

The most important rule is never force an airtight zipper. These zippers have much higher resistance than regular zippers due to their sealing mechanisms. Forcing them will damage the sealing surfaces and compromise performance permanently.

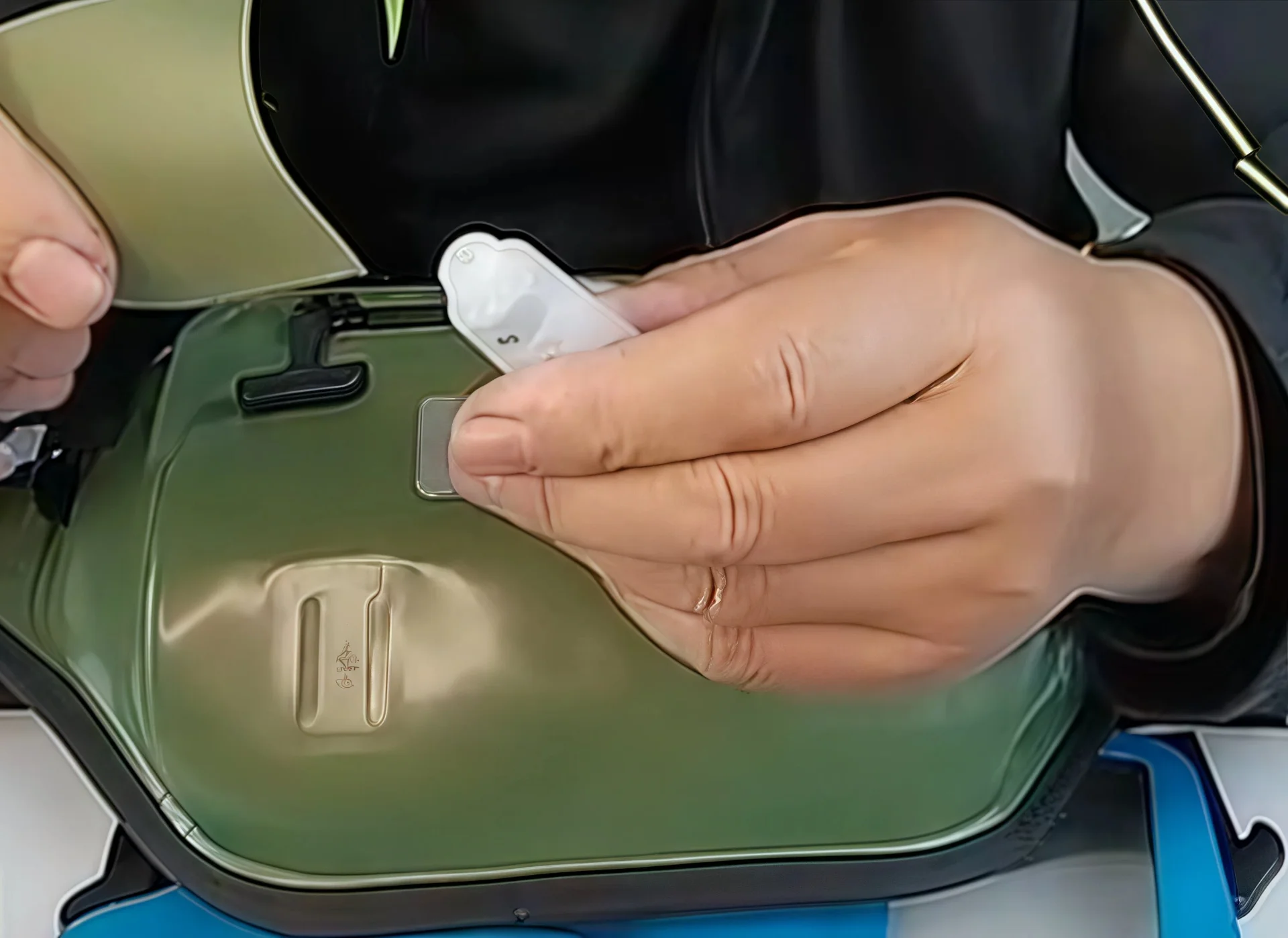

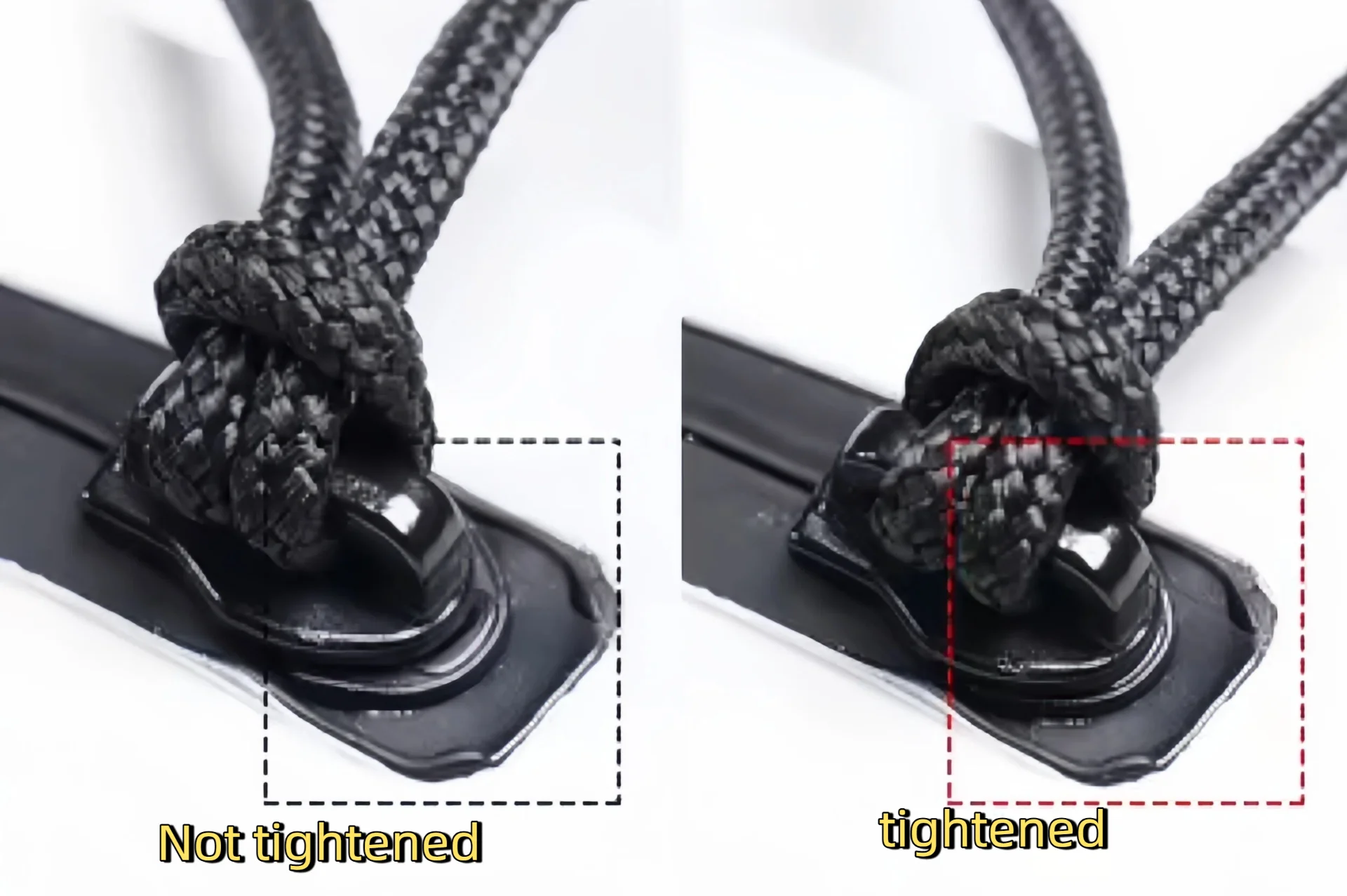

When closing, start slowly and build up speed as you approach the final position. The last few millimeters require the most force because this is where the final compression seal forms. Use steady pressure rather than quick jerks to ensure proper sealing engagement.

After closing, always test the seal. Gently squeeze the sealed area while listening for air leaks. If you hear hissing sounds, the seal isn't complete. Open and retry the closing process. For underwater applications, this test can prevent dangerous equipment failure.

Maintenance is crucial for long-term performance. Clean with fresh water after each use, especially in saltwater environments. Apply appropriate lubricants to reduce wear and ensure smooth operation. We include silicone grease with our products, but never apply lubricants directly to sealing surfaces.

Maintenance is crucial for long-term performance. Clean with fresh water after each use, especially in saltwater environments. Apply appropriate lubricants to reduce wear and ensure smooth operation. We include silicone grease with our products, but never apply lubricants directly to sealing surfaces.

Storage requires careful attention. Never fold or bend airtight zippers during storage, as this can damage the sealing materials. If problems occur, contact your supplier immediately rather than attempting repairs yourself. Professional assessment can often save an expensive zipper that might seem damaged.

Conclusion

Airtight zippers represent sophisticated engineering that enables safety and performance across critical applications, from life-saving diving equipment to industrial protection systems.

Explore the advantages of woven nylon zippers, known for their flexibility and strength, ideal for various applications. ↩

Learn about resin zippers, their chemical resistance, and why they're favored in industrial settings. ↩

Find out how AQUASEAL technology enhances zipper performance in harsh environments. ↩

Discover the durability and strength of metal zippers, perfect for high-pressure applications. ↩

Understand the features of YKK's PROSEAL zippers, known for their robust sealing capabilities. ↩

Explore the critical role of airtight zippers in ensuring safety and performance in diving gear. ↩

Learn about the stringent demands for zippers in aerospace applications and their sealing effectiveness. ↩

Discover how airtight zippers safeguard sensitive items from moisture and contamination. ↩

Understand the key elements that influence how well zippers maintain their airtight seals. ↩

Explore the benefits of TPU compounds, especially their UV resistance for outdoor applications. ↩

Learn how self-lubricating zippers enhance performance and reduce maintenance needs. ↩

Find tips on maintaining and using airtight zippers for longevity and effectiveness. ↩