The Ultimate Guide to Nylon Zippers1: Why They're Everywhere and What's So Special About Them

Nylon zippers are everywhere. Look at your coat, check your backpack, even look inside your tent. It's very likely that everything around you is a nylon zipper. These seemingly insignificant zippers play a vital role in our daily lives, yet most people never really think about them. I remember feeling like I'd opened a new world when I first noticed how many products used nylon zippers. Suddenly, I couldn't ignore their presence in coats, bags, and even medical equipment. What makes nylon zippers so popular? Let's delve into these versatile zippers and explore their unique features.

The Structure of Nylon Zippers2

Nylon zippers look simple, but they're actually quite complex. The most common type is the spiral zipper, also known as nylon coil zippers. Unlike the single teeth of a metal zipper, a nylon zipper is made up of a continuous spiral of nylon thread. I discovered this when I took apart an old jacket to repair it—the zipper unfolded as easily as a spring! This coil is sewn onto a fabric strip that is attached to clothing or equipment. Pull the zipper pull to tighten the coil and close it; push the coil away to open it. Sounds simple, right? But there's more to it than that.

The fabric tape securing the coil is just as important as the coil itself. It needs to be strong enough to withstand tension, yet flexible enough to accommodate the fabric's stretch and contraction. I've learned this the hard way, trying to replace the zipper on a thick coat with a tape that was too stiff. The coat could barely bend! Pulling the zipper pull must be perfectly coordinated with the coil—not too loose, not too tight. Just right. It's like Goldilocks testing the porridge—everything must be in perfect balance for the zipper to work smoothly.

The fabric tape securing the coil is just as important as the coil itself. It needs to be strong enough to withstand tension, yet flexible enough to accommodate the fabric's stretch and contraction. I've learned this the hard way, trying to replace the zipper on a thick coat with a tape that was too stiff. The coat could barely bend! Pulling the zipper pull must be perfectly coordinated with the coil—not too loose, not too tight. Just right. It's like Goldilocks testing the porridge—everything must be in perfect balance for the zipper to work smoothly.

Nylon3 vs. Other Materials4: What Makes Nylon3 Unique?

Metal zipper pulls are sturdy and attractive, but heavy and prone to rust. Plastic zippers are brightly colored and inexpensive, but easily damaged in cold weather. Nylon zippers? They perfectly balance these advantages. They are lightweight yet strong, flexible yet durable. I remember comparing nylon and metal zippers on backpacks—nylon zippers felt much lighter and didn't add bulk to the backpack. This makes nylon zippers ideal for outdoor gear, where every ounce of weight matters.

Nylon's flexibility is unmatched by metal or plastic. Try bending a metal zipper 180 degrees—it will knot or break. Nylon? It springs back to its original shape. A metal zipper simply becomes unusable. This flexibility makes nylon zippers perfect for irregular shapes and confined spaces.

Nylon also boasts superior water and chemical resistance compared to many other materials. This makes nylon zippers ideal for medical equipment, outdoor gear, and anything that might come into contact with liquids or corrosive substances.

Dive Deeper: The Manufacturing Process5 of Nylon Zippers6

The manufacture of nylon zippers is far more complex than you might imagine. It all starts with nylon thread—not ordinary nylon thread, but a special grade of nylon thread capable of withstanding thousands of opening and closing cycles. I once saw a very interesting video about the manufacturing process. Nylon thread is wound onto a spool and then fed into a machine to be woven into coils. These coils are then heat-set to maintain their shape, making them elastic and resilient. The finished nylon coil zippers are often sold as a zipper roll, which allows manufacturers to cut exact lengths for different applications.

The fabric tape also requires a separate pre-treatment process. They are treated to resist abrasion and dyed to precisely match the color of the coils. Color matching is crucial—I once encountered a batch of fabric tape whose color was slightly different from the coils, resulting in a poorly finished product. Afterward, the fabric tape is coated with a special adhesive to help the coils bond firmly. This adhesive must be strong enough to withstand pressure, yet flexible enough to move with the fabric.

The manufacturing process of zipper pulls is extremely complex. Each zipper pull contains teeth that engage with the coils, a spring mechanism to generate tension, and a comfortable pull tab. I've disassembled zipper pulls to study their workings, and their precise engineering is impressive. All components must fit perfectly—too loose and the zipper won't zip up; too tight and it's difficult to pull. From the size of the teeth to the strength of the springs, every detail is critical.

Where You'll Find Nylon Zippers7 (and Why)

Take a look at your wardrobe. Your jackets, hoodies, and sweatshirts most likely use nylon zippers. A nylon zipper jacket is particularly common because these zippers are lightweight, comfortable, and stretch with movement. I noticed this when comparing my winter and spring coats—both had nylon zippers, but the winter coat's zipper pulls were larger to accommodate thicker fabrics. Sportswear also uses nylon zippers extensively because of their flexibility and moisture-wicking properties. I remember my running jacket—the nylon zipper helped wick away sweat and was both windproof and waterproof.

Outdoor gear also loves nylon zippers. Tents, sleeping bags, and backpacks all use them. When I bought a new tent, the salesperson specifically pointed out that nylon zippers were effective at waterproofing and would fit perfectly with soft tent fabrics. Medical equipment also frequently uses nylon zippers because they can be repeatedly sterilized. I noticed this when I went to the hospital—all the patients' gowns and medical bags had nylon zippers that looked brand new, even after frequent use.

Fashion designers choose nylon zippers because of their versatility. It can be made into an invisible zipper for a clean and stylish look, or a decorative zipper to express individuality. Dresses almost always use invisible nylon zippers, completely hidden in the seams—almost invisible. For bags and luggage, nylon zippers offer both security and durability. Nylon tote bags with zipper are particularly popular because the zipper provides security while maintaining the bag's lightweight nature. The nylon zipper on my travel backpack has withstood years of airport "brutality" and is still in perfect condition.

Dive Deeper: The Manufacturing Process8 of Nylon Zippers9

Nylon zippers weren't always as ubiquitous as they are today. When they first appeared in the 1930s, they were seen as a cheap alternative to metal zippers. I once read an old fashion magazine that described nylon zippers as "inferior" to real metal zippers. But World War II changed everything. The military needed lightweight and durable zippers for uniforms and equipment. Nylon zippers perfectly met this need, and their reputation began to rise.

The real breakthrough came in the 1960s with the invention of the spiral zipper. Manufacturers no longer weave individual zipper teeth onto nylon tape as they used to; instead, they began producing continuous nylon spirals. This increased production speed and enhanced zipper reliability. The innovation of nylon coil zippers opened up new possibilities for apparel and equipment manufacturers, allowing for more flexible and durable fastening solutions.

Modern nylon zippers incorporate technologies unimaginable to earlier manufacturers. Self-healing zippers can repair minor damage. Waterproof zippers feature special sealing gaskets that create a seal. Antibacterial treatments prevent bacterial growth, making them ideal for medical applications. Even zipper pulls have been improved—from simple fabric loops to ergonomic, comfortable designs.

Common Nylon Zipper Problems10 (and Solutions)

While reliable, nylon zippers are not without their flaws. The most common problem is zipper pull derailment. This happened to my favorite nylon zipper jacket before a trip. I found that if the zipper pull is loose, it can be gently tightened with pliers. However, excessive force can damage the zipper pull, so be careful. Another problem is zipper tape wear, especially with repeated jamming.

Cold weather can make nylon zippers stiff and difficult to pull. I encountered this problem on a ski trip when the zipper on my ski suit completely froze. The solution is simple: heat it with your hands or a hairdryer. If the zipper is still stiff, apply a small amount of zipper lubricant. I now keep a travel-sized tube of lubricant in my ski suit. Another annoying situation is when the zipper head gets stuck in the fabric on the inside of the zipper. Don't pull hard (this can damage the zipper teeth), but gently pull the zipper head back to readjust the fabric position. Patience is key!

How to Choose the Right11 Nylon Zipper12 for Your Project

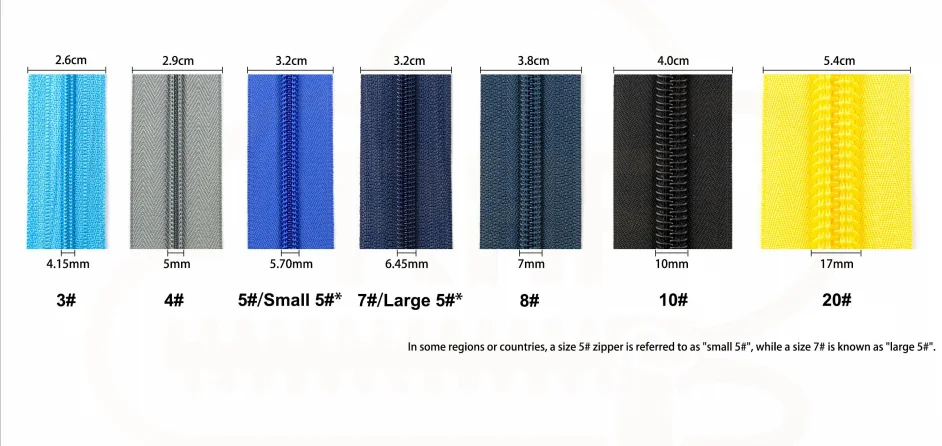

Not all nylon zippers are created equal. The size of the zipper teeth affects the zipper's strength and appearance. Smaller loops (#3-#5) are suitable for lightweight items like dresses or shirts. Larger loops (#8-#10) are suitable for heavier items like jackets or tents. The zipper length should also match your project—too short and it won't zip up, too long and it looks bulky. When purchasing in bulk, a zipper roll allows you to cut custom lengths for different applications.

Also consider the width of the zipper tape. Standard-width zipper straps are suitable for most projects, but heavy-duty projects require wider straps. The color of the zipper strap is also important, affecting visibility and aesthetics. For concealed zippers, choose a color similar to the fabric. For decorative zippers, contrasting colors can add visual interest.

Depending on the intended use, some special features may be required. Waterproof zippers have sealed edges. Zipper pulls with locks prevent accidental opening. Two-way zipper pulls open from both ends—ideal for jackets or tents. Before choosing zipper features, carefully consider how your items will be used.

Dive Deeper: Customizing Nylon Zippers13 for Specific Needs14

Nylon zippers can be customized in many ways to meet specific needs. The shape of the zipper pull affects comfort and ease of use. Large, easy-to-grip zipper pulls are suitable for gloves or winter clothing, as standard zipper pulls are simply unusable with cold fingers. Zipper pulls can be made from a variety of materials—plastic, leather, fabric—each with different textures and durability. I replaced the metal zipper pulls on my work bag with leather ones so my hands wouldn't get cold in winter.

Custom reflective tape is also a great option. Reflective tape improves the visibility of safety gear. I added reflective zipper tape to my cycling jacket for easier riding in the morning. Waterproof tape helps prevent moisture damage. For items that require frequent washing, I opted for tape treated with anti-mildew and anti-fading agents. Colored tape can match or contrast with your project. When working with nylon tote bags with zipper, choosing the right tape color can enhance the overall aesthetic while maintaining functionality.

The Future of Nylon Zippers

Nylon zippers are constantly evolving with the emergence of new materials and technologies. Recycled nylon is becoming increasingly common, reducing environmental impact. I've been working with a supplier who uses recycled plastic bottles to make zippers—and they perform exactly like traditional nylon zippers. Smart zippers with electronic components can track usage or provide security. I've seen a prototype jacket whose zipper can be electronically locked via a smartphone app.

Sustainable manufacturing processes are reducing waste and energy consumption. Water-based dyes and adhesives are replacing harmful chemicals. I visited a factory where they had completely stopped using toxic solvents in their production process—air quality has noticeably improved. 3D printing technology has made it possible to design custom zipper pulls, something previously impossible. I've tried printing my own custom zipper pulls to meet my specific needs and aesthetic preferences.

The future of nylon zippers is bright. With advancements in materials science, we can expect stronger, lighter, and more environmentally friendly options. Smart features will become increasingly common, adding more functionality to zippers than just simple fasteners. I'm excited to see how nylon zippers will continue to evolve and what new possibilities they will bring to designers and manufacturers worldwide.

Conclusion

Nylon zippers are the unsung heroes of the fastener world. Their lightweight, flexibility, durability, and versatility make them ideal for countless applications. From everyday clothing to professional gear, nylon zippers reliably and efficiently accomplish a variety of tasks. Whether you're looking for nylon coil zippers for your next sewing project, shopping for a reliable nylon zipper jacket, or need nylon tote bags with zipper for daily use, understanding these fasteners helps you make better choices. The next time you use a nylon zipper, take a moment to appreciate the craftsmanship behind this seemingly simple device. If you need custom nylon zippers for your projects, contact us—we can help you find the most suitable solution. Remember, the right zipper is crucial to both the performance and appearance of your product. Make a wise choice, and your work will surely thank you!

Discover the advantages of Nylon Zippers, including durability and versatility, which make them a popular choice in various applications. ↩

Explore the advantages of Nylon Zippers to understand their durability and versatility in various applications. ↩

Discover the distinct characteristics of Nylon that set it apart from other fabrics, enhancing your understanding of material choices. ↩

Explore the benefits of various materials to see how they compare with Nylon, helping you make informed decisions for your projects. ↩

Understanding the manufacturing process can enhance your knowledge of quality and durability in nylon zippers. ↩

Exploring the benefits of nylon zippers can help you make informed choices for your projects. ↩

Explore this link to find a variety of Nylon Zippers for your projects, ensuring quality and durability. ↩

Understanding the manufacturing process can enhance your knowledge of quality and durability in nylon zippers. ↩

Exploring the benefits of nylon zippers can help you make informed choices for your projects. ↩

Understanding common issues with nylon zippers can help you troubleshoot effectively and extend the life of your items. ↩

This resource will guide you in selecting the best materials for your sewing projects, enhancing your overall crafting experience. ↩

Explore this link to understand the various types of Nylon Zippers and their specific uses, ensuring you choose the right one for your project. ↩

Explore this link to discover innovative techniques and tips for customizing nylon zippers to meet your specific needs. ↩

This resource will guide you in selecting the right zippers tailored to your specific needs, ensuring functionality and style. ↩