Zipper Always Stuck or Broken? How to Identify a Truly High-Quality Zipper

The difference between a high-quality zipper1 and a low-quality one is like the difference between a luxury car and a basic commuter car—superficially, they both fulfill the basic function, but they are worlds apart in terms of user experience, durability, and sense of quality. So, what makes a zipper a high-quality zipper1? Let's explore the secrets of this precise little world.

The Self-Cultivation of an "Excellent" Zipper

A good zipper should glide smoothly like flowing clouds when opening and closing, with no catching or stiffness. Even after thousands of repeated cycles, it should maintain a consistent feel. For instance, zippers for coats designed for winter must not only handle material stability in low temperatures but also adapt to the pull of heavy fabrics. If the smoothness is insufficient, it's easy to encounter the awkward situation of "getting stuck halfway," affecting the wearing experience. We have compared many zippers, and high-quality ones have tightly interlocking and smoothly polished teeth, paired with a high-quality pull tab3, allowing for easy one-handed operation.

- Material and Craftsmanship are the "Core Support" of Quality

The durability of a zipper depends directly on its material. A high-quality zipper can withstand tens of thousands of open/close tests without deformation. The YKK brass zipper4 in the metal zipper category is an industry benchmark. Brass has natural corrosion resistance, good luster, and effectively resists wear from moisture and friction. Whether used in outdoor clothing or frequently used bags, it ensures long-lasting durability. In terms of craftsmanship, high-quality zippers have neatly aligned teeth and tight stitching, with no "misaligned teeth" or "loose threads." The edges are smoothly polished without burrs to avoid snagging fabric. Well-known brands like Wawak Zippers5 have become the preferred trims for many high-end brands due to their strict material selection and meticulous process control.

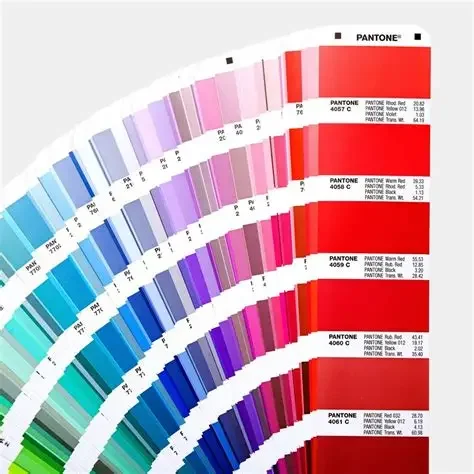

- Color Matching Accuracy is the "Invisible Bonus" of Quality

For apparel and bag brands, the zipper color must perfectly match the fabric to ensure the overall design's consistency. Professional color cards like the YKK zipper color card6, GCC International Textile Industry Standard Color Card, and Pantone Color Card7 cover hundreds of precise color options, meeting the needs of different fabrics and design styles. High-quality zippers use professional dyeing processes with minimal color difference and high color fastness. Even after multiple washes or prolonged sun exposure, they won't fade or discolor, maintaining consistent aesthetics with the fabric. This detailed color management allows designers to find the ideal matching solution.

- Compatibility and Safety are the "Ultimate Test" of Quality

High-quality zippers are not "one-size-fits-all"; they are designed for specific usage scenarios. For example, zippers for coats might have added windproof and waterproof coatings to suit winter outdoor environments; bag zippers might have thicker teeth and reinforced sliders to enhance load-bearing capacity. At the same time, the materials of high-quality zippers8 comply with international environmental standards—odorless and free of harmful substances. Especially for children's wear and maternity/baby products, zippers may include anti-pinch designs9, balancing practicality and safety.

The Four Essential Standards for High-Quality Zippers

Premium Materials and Craftsmanship

The spacing between each tooth is precise to the millimeter level, and the tape weave density is uniform. These seemingly minor details are key to distinguishing ordinary zippers from high-end ones.

Teeth/Coil:

- Metal: Made from high-quality brass10, nickel, or aluminum alloy with even and durable plating. Teeth are precisely formed and securely fastened.

- Nylon/Plastic Molded: Made from virgin polymer resin, flexible and sturdy. Coils are uniform with no wear or deformation.

- Injection Molded (Vislon): Precisely injection molded to ensure perfect alignment and smooth engagement.

Tape: Woven from high-density polyester11 or nylon. High strength, good color fastness, tight weave to prevent stretching or fraying. Often treated for water resistance or UV protection.

Slider and Pull Tab: Precision-made from durable metal or reinforced polymer. Internal mechanism firmly engages the teeth. Pull tab is securely attached (often with a non-rotating stopper). Edges are smooth to avoid snagging fabric.

Top/Bottom Stops: Securely riveted or molded to prevent slider from running off or separating.

Exceptional Performance and Durability

Smooth Operation: Effortless and fluid movement with minimal resistance, even on curves or under tension—no catching, sticking, or "puckering."

High Strength12: Withstands significant pulling force without separating. The slider, teeth/coils, and tape are all engineered to withstand pressures beyond normal use (e.g., on a packed suitcase or tight-fitting garment).

Long Service Life13: Can endure thousands of open/close cycles without significant wear. Resistant to corrosion, abrasion, and UV damage.

Perfect Appearance Presentation

The slider surface14 is smooth without burrs, plating is even and lustrous, and tape edges are neat without loose threads. These visual details not only affect aesthetics but also reflect the manufacturer's craftsmanship15.

Strict Standards and Certifications

Safety and Compliance: Meets or exceeds international safety standards (e.g., no sharp edges, lead-free, phthalate-free).

Environmental Standards: Often complies with OEKO-TEX Standard 10016 (free from harmful substances), REACH, or uses GRS-certified recycled materials.

Performance Testing: Provides formal test reports covering strength (e.g., BS 3084, ASTM D2061), color fastness, abrasion resistance, salt spray testing, etc.

Practical Tips for Choosing High-Quality Zippers

- Check Brand Reputation: Choose suppliers with a good market reputation.

- Feel the Quality: High-quality zippers feel smooth to the touch with no noticeable resistance.

- Verify Certifications: Confirm if the product has passed relevant quality certifications.

- Test Samples: Always test sample performance before placing a large order.

- Consider Compatibility: Select the appropriate zipper specification and material based on the garment type.

A high-quality zipper is not just a functional accessory for a garment; it is a reflection of the brand's quality. In the competitive apparel market, choosing a reliable zipper supplier is like taking out an "insurance policy" for your product's quality.

As a professional supplier of apparel trims and accessories, we deeply understand the importance of every detail for the final product's quality. If you are looking for a trustworthy zipper partner, feel free to contact us. Let our professional experience add perfect quality to your products!

Want to learn more professional knowledge about high-quality zippers? Welcome to follow our website for the latest industry news and product information.

Understanding the traits of high-quality zippers can help you make informed choices for durability and performance. ↩

Understanding zipper quality can enhance your product choices and improve user experience. ↩

Discovering the features of a high-quality pull tab can significantly improve zipper functionality and ease of use. ↩

Discover why YKK brass zippers are considered the best in the industry for durability and quality. ↩

Learn about Wawak Zippers' meticulous craftsmanship and material selection that appeals to luxury brands. ↩

Explore the YKK zipper color card to understand its role in achieving perfect color matching in apparel design. ↩

Discover how the Pantone Color Card aids designers in selecting precise colors for fabrics, ensuring consistency and quality. ↩

Discover the essential features that make high-quality zippers durable and reliable for various applications. ↩

Learn how anti-pinch designs enhance safety in zippers, especially for children's wear and baby products. ↩

Explore the advantages of high-quality brass in zippers, including durability and aesthetic appeal. ↩

Learn about the strength and durability of high-density polyester, crucial for long-lasting zippers. ↩

Discover how high strength zippers enhance durability and performance in various applications. ↩

Learn about the advantages of long service life zippers and their impact on cost-effectiveness. ↩

Understanding the importance of a smooth slider surface can enhance your knowledge of quality manufacturing and craftsmanship. ↩

Exploring this topic will provide insights into how craftsmanship influences the durability and appeal of products. ↩

Understanding OEKO-TEX Standard 100 can help you ensure the safety and quality of textiles, making it essential for informed purchasing. ↩