Zipper Testing: The Rigorous Trials You Can't See That Determine Ultimate Product Quality

When you unzip a high-end jacket or open a travel suitcase, have you ever wondered how many tests that small zipper has endured before reaching your hands? As a global supply chain partner for brands worldwide, we understand that every inch of zipper carries the weight of product reputation. Today, let's step into our professional laboratory and witness the "ultimate challenges" that every qualified zipper must pass.

Chapter 1: The "Strength Test1" - How Much Pressure Can It Withstand?

Imagine a fully packed suitcase falling from a conveyor belt, or an outdoor jacket getting caught on branches during mountain climbing - how much force does a zipper need to resist "breakdown"? Strength testing is the core of zipper evaluation, conducted entirely on computer-controlled electronic universal material testing machines. The equipment automatically generates force-displacement curves with objective, tamper-proof data.

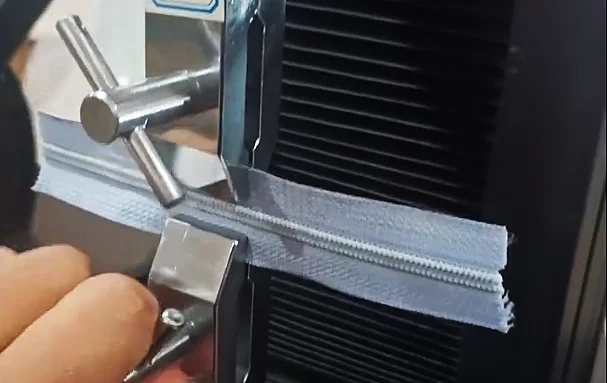

Lateral Tensile Strength Test2

This simulates scenarios of overpacked luggage or violently pulled backpacks. We secure both ends of a closed zipper to an electronic tensile machine and stretch it laterally at 300mm/minute until the zipper fails.

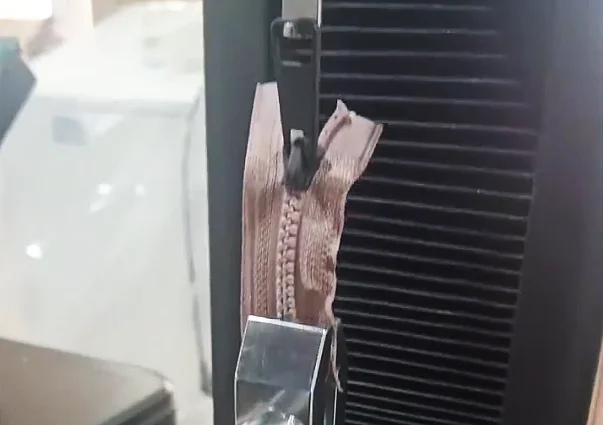

2. Zipper Self-Lock Strength Test

This evaluates the slider's ability to maintain self-locking3 when the zipper is closed. During testing, we pull the slider to the middle position of the zipper, ensuring it's in a self-locked state. The upper clamp grips one tape (approximately 75mm from the slider); the lower clamp grips the other tape (at a symmetrical position, ensuring the zipper is vertical without skew). We start the tensile machine with clamps separating in opposite directions, continuing until the slider moves (self-lock failure) or the zipper tape/teeth are damaged.

3. Top Stop/Bottom Stop Strength Test

This focuses on another weak point of zippers - whether the slider will detach.

Top Stop Strength Test4: Close the zipper so the slider contacts the top stop. Thread the slider pull tab through a hook to secure the zipper in the machine's lower clamp. Start the machine, stretching at (100±10) mm/min speed until zipper failure.

Bottom Stop Strength Test5: Open the zipper so the slider contacts the bottom stop. Clamp both free ends of the chain tapes in the machine's two clamps, stretching at (100±10) mm/min6 speed until failure.

Bottom Stop Strength Test5: Open the zipper so the slider contacts the bottom stop. Clamp both free ends of the chain tapes in the machine's two clamps, stretching at (100±10) mm/min6 speed until failure.

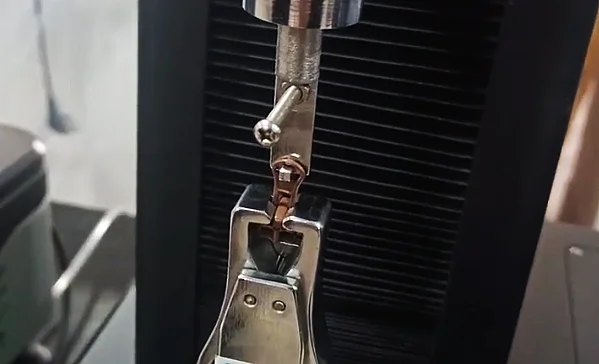

4. Single Tooth Displacement Strength Test

Using special fixtures on the tensile machine, we engage a single chain tooth and apply vertical upward force, simulating a zipper being locally caught by sharp objects until the tooth is pulled from the tape. This test directly addresses tooth grip firmness7 and is key for evaluating tooth manufacturing processes (injection molding temperature, metal tooth foot shape). Low force values indicate potential "tooth loss" under local stress, creating small parts ingestion risks.

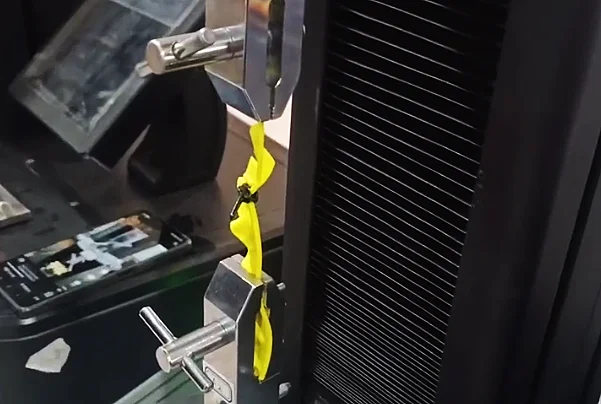

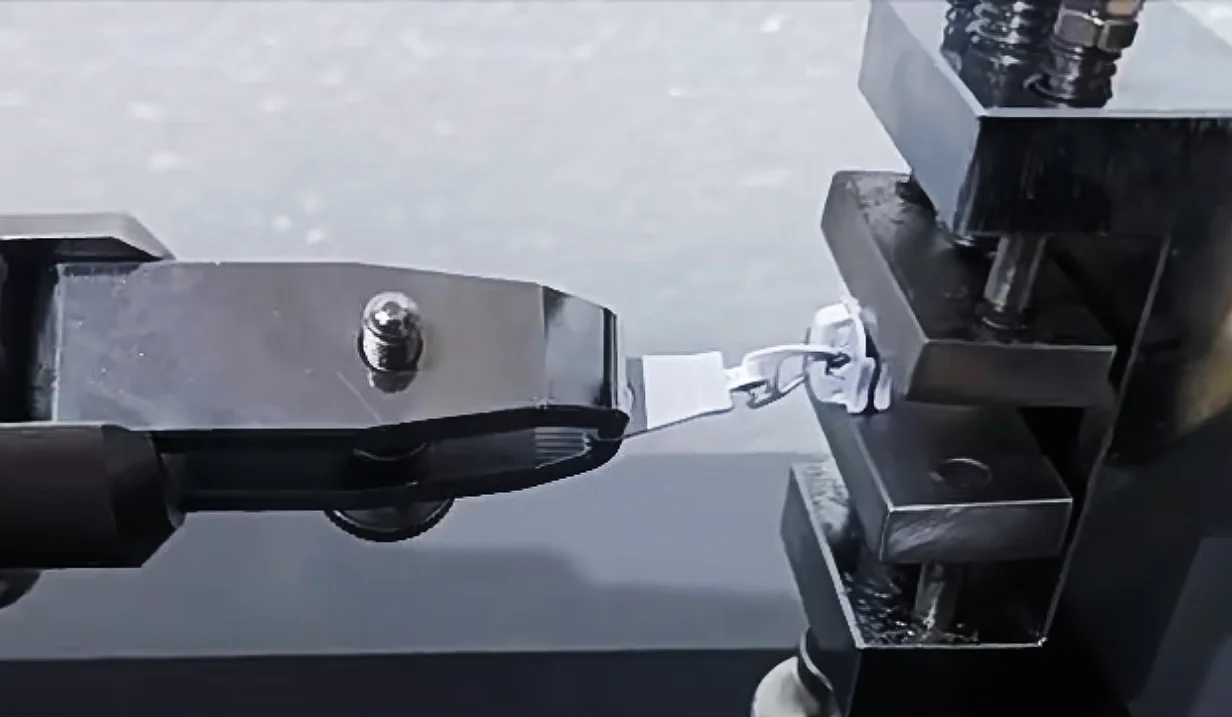

5. Pull Tab Joint Strength8 Test

This simulates excessive force when pulling the tab or children curiously hanging from the pull tab.

Pull Tab Joint Strength7: Secure the slider and stretch the pull tab vertically or at angles until the tab, puller, or connecting components detach.

This directly relates to usage safety, especially for children's clothing. US CPSIA and other regulations have implicit requirements. Testing ensures both the slider body and pull tab connections can withstand unconventional abuse.

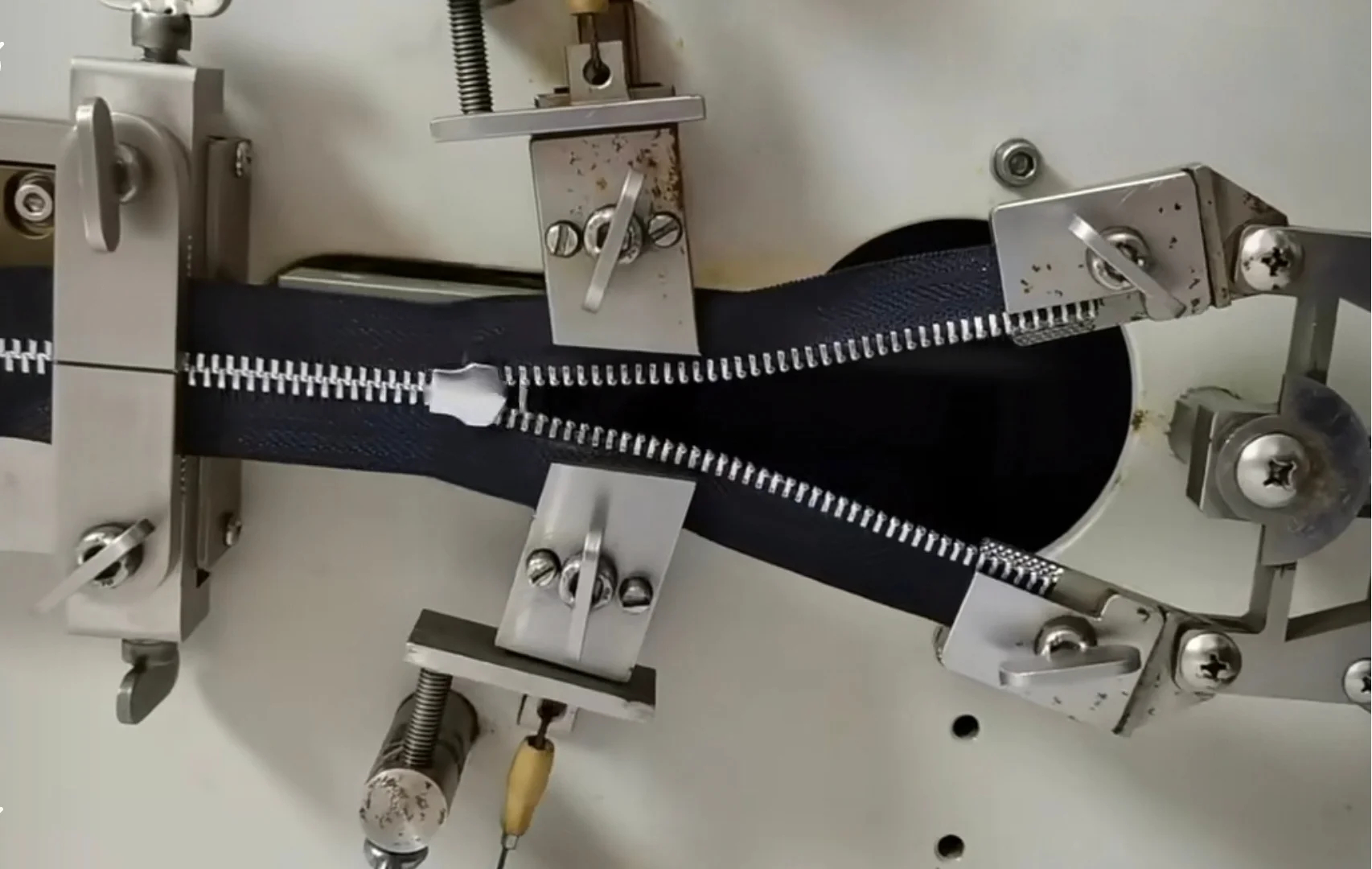

6. Double Slider Mutual Contact Strength Test (for Separating Zippers)

We pull both sliders to closed positions so they contact each other, then apply tension to both tapes, testing slider interlocking stability9 and chain tooth compression resistance. This is an advanced test unique to separating zippers, preventing "bursting open" at chest level due to improper force - a hallmark of premium outerwear quality.

7. Slider Torque Resistance Test

Using specialized fixtures to secure the zipper pull tab, we apply specified directional torque to detect whether the pull tab breaks, loosens, or detaches from the slider. This verifies the firmness of pull tab connections10 (riveting/welding/injection molding), prevents consumer complaints or product recalls due to pull tab breakage, and meets brand customer or international standard requirements (ASTM, ISO, QB/T).

Conducting different types of strength tests on zippers11 is far more complex than simply "checking if it's sturdy." Each test corresponds to specific risks in real-world usage scenarios and serves as a critical defense line for ensuring product functionality12, safety, lifespan, and brand reputation.

Conducting different types of strength tests on zippers11 is far more complex than simply "checking if it's sturdy." Each test corresponds to specific risks in real-world usage scenarios and serves as a critical defense line for ensuring product functionality12, safety, lifespan, and brand reputation.

Chapter 2: The Endurance Marathon - "Lifecycle" Verification of a Zipper

If strength testing is a "sprint," then cyclic fatigue testing13 is a marathon. On reciprocating fatigue testing machines, sliders move back and forth on zippers at 30 cycles per minute, simulating years of product wear.

Testing standards vary by application:

- Regular garment zippers: ≥500 cycles

- High-quality luggage zippers: ≥2000 cycles

- Professional outdoor equipment zippers: ≥5000 cycles

After testing, we not only check if the zipper functions normally but also examine under microscope:

After testing, we not only check if the zipper functions normally but also examine under microscope:

- Internal slider wear conditions

- Chain tooth shape deformation

- Tape edge fraying

- Continued smoothness

Chapter 3: Environmental Challenge - Quality Commitment from Arctic to Equator

True quality means maintaining consistent performance in any environment. Our environmental testing simulates various extreme global conditions:

| Test Item | Simulated Environment | Test Standard | Pass Criteria |

|---|---|---|---|

| Salt Spray Test14 | Coastal high humidity/salt environment | GB/T 10125 (ISO 9227) | No red rust after 72 hours |

| High-Low Temperature Cycling | -30℃ extreme cold to 70℃ high heat | ASTM D2061 | Normal function, no brittle cracking |

| Humid Heat Test | Tropical rainforest climate | ISO 4611 | No mold, normal function after 48 hours |

Real Case Example: Zippers we supplied to a Nordic outdoor brand remained smoothly operable after -35℃ low-temperature testing - demonstrating the value of rigorous environmental testing.

Real Case Example: Zippers we supplied to a Nordic outdoor brand remained smoothly operable after -35℃ low-temperature testing - demonstrating the value of rigorous environmental testing.

Chapter 4: Safety and Environmental Protection - "Passport" for International Markets

This represents the highest technical barriers and most mandatory requirements, directly affecting whether products can clear customs in target markets.

Testing Process Overview:

-

Sampling and Pre-treatment: Shred different zipper material components (polyester tape, polyester chain teeth, metal plating), followed by acid digestion or solvent extraction.

-

Instrumental Analysis:

- Heavy metals (lead, cadmium, mercury, etc.)15: Using Inductively Coupled Plasma Mass Spectrometry (ICP-MS) with detection precision to parts-per-billion (ppb) levels.

- Azo dyes, plasticizers, formaldehyde: Using Gas Chromatography-Mass Spectrometry (GC-MS)16 for precise qualitative and quantitative analysis.

- Data Comparison and Determination: Compare results against regulatory limits and issue compliance reports.

Major International Regulations and Certifications:

| Regulation/Certification | Market Jurisdiction | Core Controlled Substances | Significance to Our Company |

|---|---|---|---|

| EU REACH Regulation17 | European Economic Area | Over 2000 Substances of Very High Concern (SVHC), including specific plasticizers and heavy metals | Mandatory. We maintain SVHC databases ensuring every raw material batch complies |

| US CPSIA | United States | Lead, phthalates (plasticizers) | Mandatory. Especially for children's products - our children's clothing zippers all pass CPSC-accepted laboratory testing |

| OEKO-TEX® Standard 10018 | Global (voluntary certification) | Covers 300+ harmful substances, stricter than legal standards | Proactive quality declaration. Multiple product lines certified, adding value for customer brands |

Chapter 5: Details Determine Success - Those Easily Overlooked Tests

Beyond the major "examinations," zippers must pass numerous "minor tests":

Smoothness Testing

Sensors record force variations during zipper opening/closing, ensuring smooth, uniform feel. Ideal curves should be stable wave lines, not dramatic peaks and valleys.

Color Fastness Testing

Including resistance to rubbing, washing, and light exposure, ensuring zipper tape colors remain stable under various conditions. We use grey scales for 1-5 grade evaluation, with export products typically requiring grade 4 or above.

Dimensional Accuracy Measurement

Ensures every millimeter is precisely accurate. Using projectors and calipers, we check:

- Tape width deviation within ±0.5mm

- Consistent chain tooth height

- Slider-to-chain tooth compatibility

Our Promise: Every Inch Withstands Scrutiny

After seeing these rigorous tests, you may understand why a quality zipper requires such a complex quality system. At our company, "Testing isn't the final checkpoint - it's the standard throughout the entire process."

From raw material receipt to finished product shipment, every zipper batch undergoes:

Triple Testing System:

- Raw material inspection

- Production process sampling

- Finished product comprehensive testing

Dual Standard Verification:

- Internal laboratory monitoring + regular international third-party verification

Traceability Management:

- Every zipper roll has independent batch numbers with full quality traceability

We provide zipper solutions for customers in over 30 countries, covering garments, luggage, outdoor equipment, home goods, and more. Whether you need high-environmental zippers meeting EU REACH standards, or professional outdoor zippers passing 5000 fatigue cycles, we can customize solutions for you.

If you're seeking a zipper partner with confirmed performance data, complete safety documentation, and products that withstand global market scrutiny for your next season, we're ready.

See for Yourself, Feel the Quality

We sincerely invite you to request our free sample kit and personally experience:

- Different material zipper feel (nylon, resin, metal)

- Original test report data

- Customized solution recommendations for your specific applications

Please contact us through our website contact form or email directly at: [email protected] to receive samples. Let us secure your products with zippers that pass every test - your "Certificate of Quality."

Understanding the Strength Test is crucial for ensuring zipper durability and reliability in high-quality products. ↩

Exploring this test reveals the rigorous standards zippers must meet, ensuring they can withstand extreme conditions. ↩

Understanding self-locking mechanisms in zippers can enhance your knowledge of zipper durability and performance. ↩

Exploring the Top Stop Strength Test will provide insights into zipper reliability and design weaknesses. ↩

Understanding this test is crucial for ensuring zipper durability and quality in manufacturing. ↩

This speed is vital for accurate testing results, ensuring consistent and reliable data in material strength assessments. ↩

Understanding tooth grip firmness is crucial for ensuring zipper durability and safety, especially in children's clothing. ↩

Exploring Pull Tab Joint Strength testing methods can provide insights into safety standards and regulations for children's apparel. ↩

Understanding slider interlocking stability is crucial for ensuring zipper durability and preventing failures in high-quality outerwear. ↩

Exploring pull tab connections testing methods can provide insights into zipper reliability and help avoid product recalls. ↩

Understanding the various strength tests on zippers can help ensure product quality and safety, making it essential for manufacturers. ↩

Exploring the link between product functionality and brand reputation can provide insights into maintaining customer trust and loyalty. ↩

Understanding cyclic fatigue testing can help you appreciate its role in ensuring product longevity and reliability. ↩

Exploring the Salt Spray Test will provide insights into how corrosion resistance is measured in various materials. ↩

Understanding the health impacts of heavy metals is crucial for safety and compliance in product manufacturing. ↩

Exploring GC-MS will enhance your knowledge of its applications in ensuring product safety and quality. ↩

Understanding the EU REACH Regulation is crucial for compliance in the European market, ensuring safety and sustainability in product materials. ↩

Exploring the OEKO-TEX® Standard 100 certification can enhance product quality and consumer trust, vital for brands focusing on safety and sustainability. ↩