How Do Zippers Actually Work? The Complete Engineering Guide

We use zippers every day, but few people understand how they work. With 7 billion zippers produced globally every year, these small mechanical marvels deserve closer examination. Learn the engineering principles of zippers in 5 minutes.

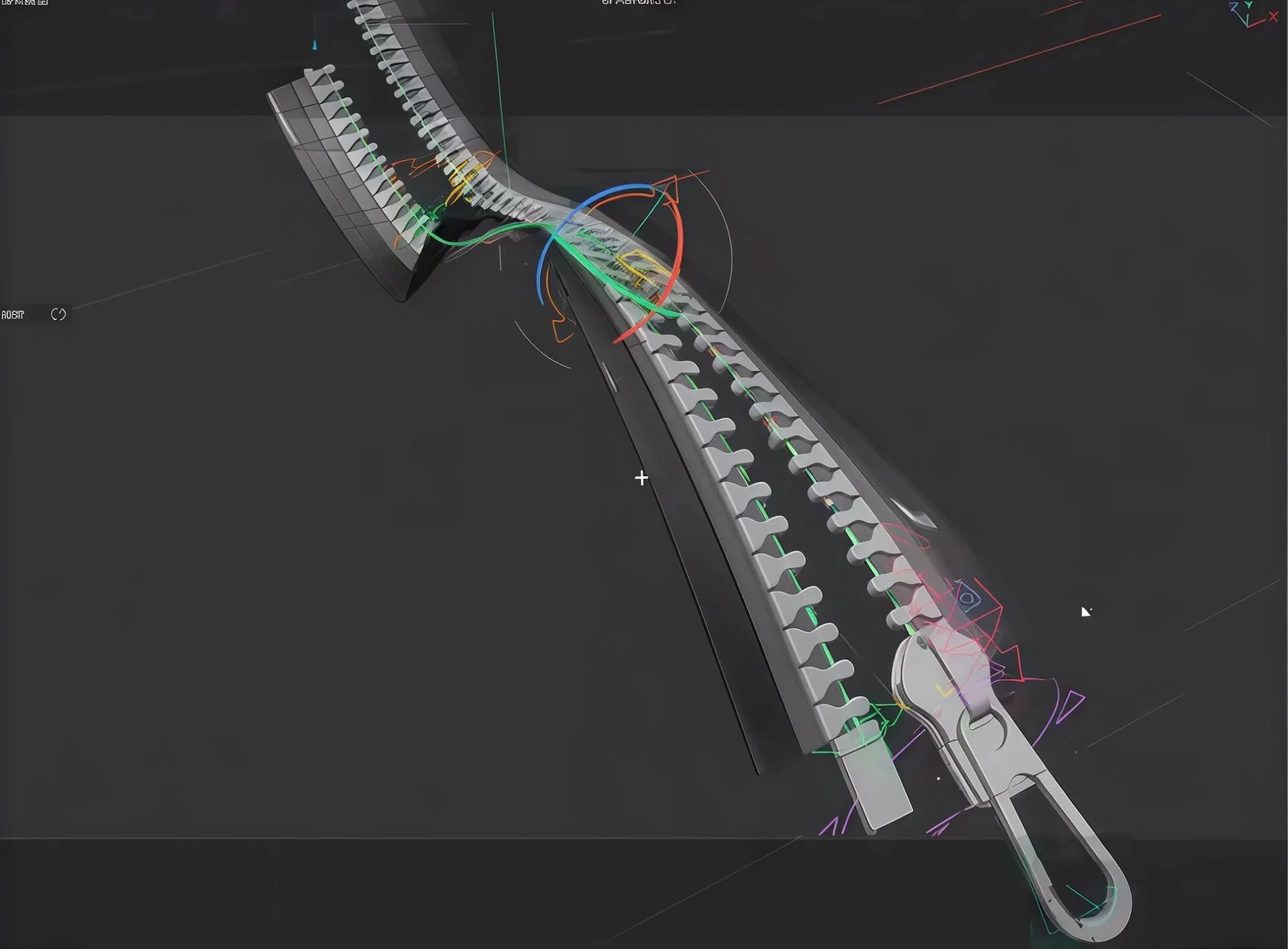

Zippers work through a simple yet ingenious Y-shaped wedge system1 that guides interlocking teeth together and apart. The zipper pull creates a 45° compression force2 that presses teeth into grooves during closing, while reverse motion separates them during opening, with each tooth handling 2-5N of force.---

I have been fascinated by zipper mechanics since I started working in the garment accessories industry. Most people take zippers for granted, but understanding their engineering helps us appreciate why quality matters so much in manufacturing.

I have been fascinated by zipper mechanics since I started working in the garment accessories industry. Most people take zippers for granted, but understanding their engineering helps us appreciate why quality matters so much in manufacturing.

What Makes the Y-Shaped Channel So Important?

Every time you pull a zipper, you witness precision engineering3 in action. The secret lies in that small Y-shaped channel4 inside the zipper pull.

The Y-shaped channel4 creates the exact angle needed for tooth engagement. When I examine zipper pulls under magnification, I can see how this channel forms two inclined surfaces that guide teeth together at precisely 45 degrees.---

The Physics Behind Wedge Action

Force Distribution5: The wedge shape distributes closing force evenly across multiple teeth. Instead of one tooth bearing all the stress, the load spreads across 8-12 teeth simultaneously. This is why quality zippers can handle repeated stress without failure.

Angle Precision6: That 45-degree angle is not random. Through years of engineering refinement, manufacturers discovered this angle provides optimal balance between easy operation and secure closure. Steeper angles require too much force. Shallower angles don't create enough compression.

Material Flow: As teeth compress together, the Y-channel guides any material deformation smoothly. This prevents jamming and ensures smooth operation even after thousands of cycles.

| Component | Function | Critical Angle |

|---|---|---|

| Upper Wedge | Compresses left teeth | 45° ± 2° |

| Lower Wedge | Compresses right teeth | 45° ± 2° |

| Exit Channel | Maintains alignment | 90° |

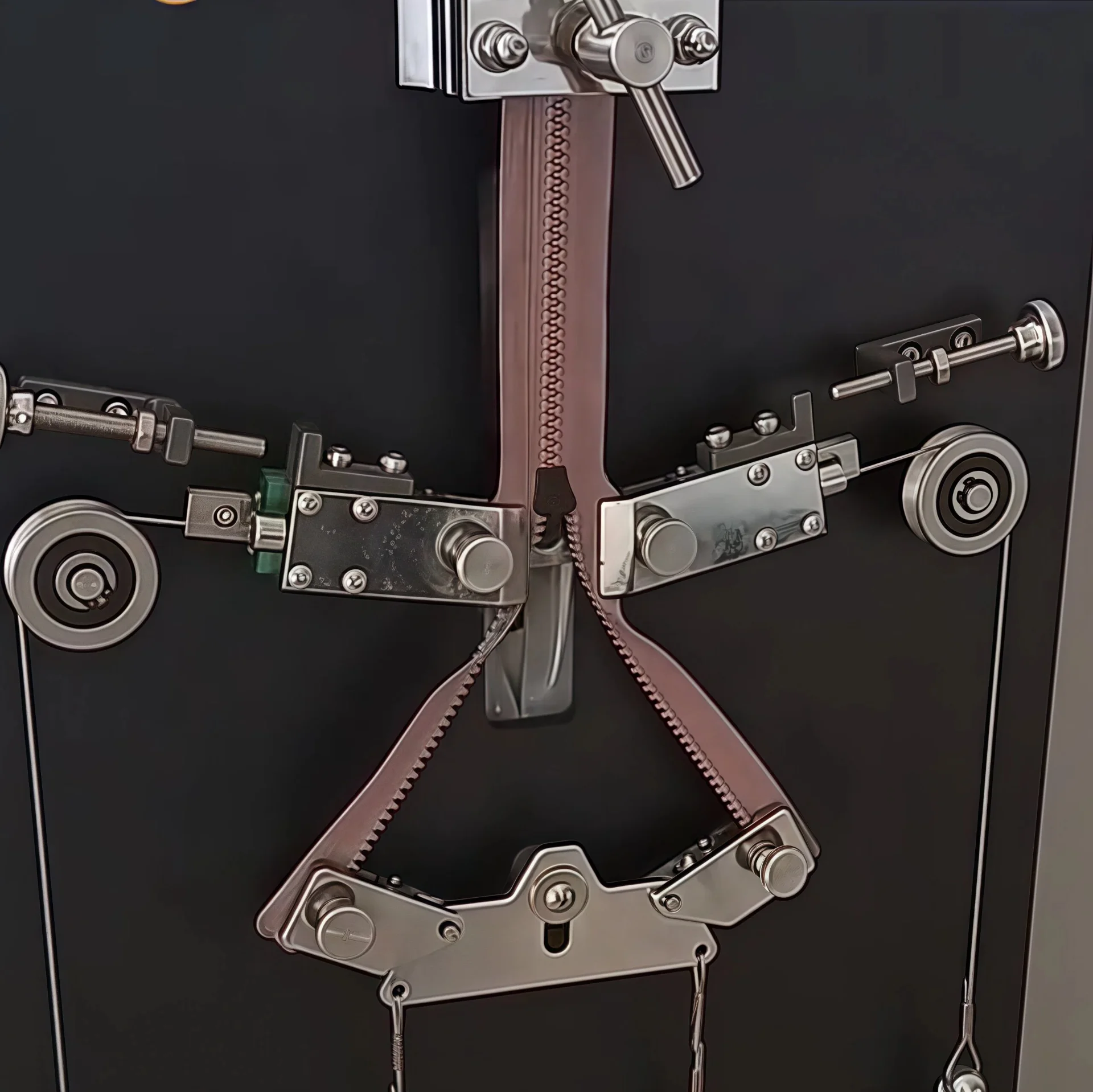

How Do Zipper Teeth Actually Interlock?

I often get asked about the actual interlocking mechanism. The answer involves understanding tooth geometry and how raised portions fit into grooves.

Each zipper tooth has a specific profile designed for maximum holding strength. The raised portion, called the "head," fits precisely into a corresponding groove on the opposite side.---

Three-Stage Interlocking Process

Stage 1 - Initial Contact: As the zipper pull approaches, teeth make first contact at their leading edges. The Y-channel begins applying lateral pressure, pushing teeth toward center alignment.

Stage 2 - Progressive Engagement: Teeth slide past each other as the wedge forces them together. The head of each tooth enters the groove of its opposite partner. This creates the primary mechanical bond.

Stage 3 - Complete Lock: Multiple teeth engage simultaneously, creating a continuous interlocked chain. Each connection reinforces the others, distributing any opening forces across the entire engaged length.

Load Distribution Data:

- Single tooth capacity: 2-5N

- Typical engagement length: 15-25 teeth

- Total holding force: 30-125N

- Safety factor: 3-5x normal use force

Why Do Zippers Sometimes Jam or Break?

After years of working with zipper manufacturers, I have identified the most common failure modes. Understanding these helps explain why quality control7 matters so much.

Zipper failures usually stem from four main causes: tooth misalignment8, excessive force application, contamination, or material fatigue.---

Root Cause Analysis

Tooth Misalignment9: When teeth don't align properly, the wedge action creates uneven forces. Instead of smooth compression, you get binding and resistance. This often happens when fabric gets caught or when pulls are bent.

Force Overload: Standard zippers handle 3-9N closing force. Excessive force can deform teeth permanently. I have seen zippers destroyed by users applying 20-30N of force during emergency situations.

Contamination Issues: Sand, lint, or dried adhesives interfere with smooth tooth engagement. The Y-channel becomes blocked, preventing proper wedge action. Regular cleaning prevents most contamination failures.

Material Fatigue10: After 5,000-50,000 cycles (depending on quality), metals experience fatigue cracking. Plastic teeth wear down gradually. This is why military and outdoor gear uses higher-grade zippers with extended cycle ratings.

| Failure Type | Typical Cause | Prevention Method |

|---|---|---|

| Tooth Breakage | Excessive force | Proper user training |

| Jamming | Contamination | Regular cleaning |

| Pull Separation | Manufacturing defect | Quality control testing |

| Fabric Tearing | Incorrect installation | Professional application |

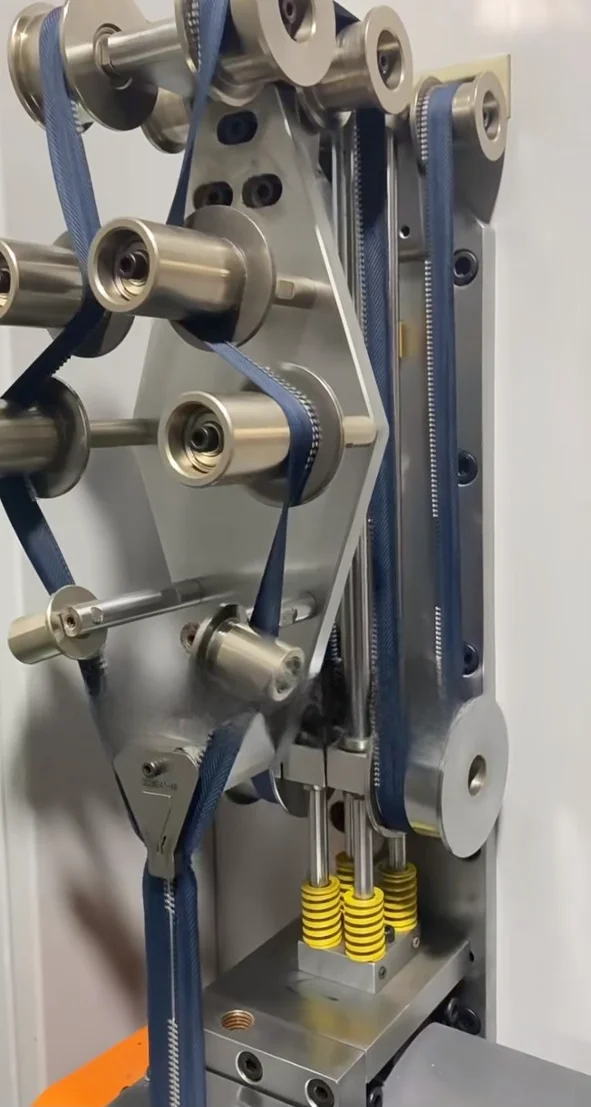

What Testing Standards Ensure Zipper Reliability?

Quality zippers undergo rigorous testing before they reach consumers. I work closely with manufacturers who implement comprehensive testing protocols.

The most critical tests measure fatigue resistance, salt spray corrosion, and force requirements. These tests simulate years of real-world use in accelerated laboratory conditions.---

### Standard Testing Protocols

### Standard Testing Protocols

Fatigue Testing11: Automated machines cycle zippers 5,000-50,000 times at specified speeds. Premium zippers must complete 25,000+ cycles without failure. I have witnessed tests where military-grade zippers complete 100,000+ cycles.

Salt Spray Testing12: Metal components undergo 48-72 hour salt spray exposure to simulate coastal environments. Proper electroplating prevents corrosion that would interfere with smooth operation.

Force Measurement: Precise instruments measure opening and closing forces throughout the zipper's length. Consistent force levels indicate proper manufacturing tolerances.

Temperature Cycling: Zippers face temperature extremes from -40°C to +70°C while maintaining functionality. This ensures reliable operation in all climates.

Testing standards vary by application:

- Apparel zippers: 5,000-15,000 cycles

- Luggage zippers: 15,000-25,000 cycles

- Marine/outdoor: 25,000-50,000 cycles

- Military/aerospace: 50,000+ cycles

How Does Holyn Textile Ensure Superior Zipper Quality?

As a professional garment accessories supplier in Shenzhen, we have developed deep understanding of every zipper production process step. My background has taught me that excellence comes from controlling each detail throughout the manufacturing chain.

Our complete industrial chain includes 8 specialized production lines covering mold opening, die casting, electroplating, and final assembly. This integration allows us to maintain consistent quality standards that many suppliers cannot match.---

Our Professional Advantages

Quality Assurance: We implement 48-72 hour salt spray testing and comprehensive fatigue/torque testing on every batch. Our ISO 9001 certified processes ensure consistent results that meet international standards.

Rapid Prototyping: Our streamlined sampling process delivers completed prototypes in 48-72 hours. This speed helps our clients accelerate their product development while ensuring mass production consistency.

Compliance Excellence: We maintain pre-configured EU/US compliance document packages including complete RoHS/REACH/OEKO-TEX reports. This eliminates compliance delays that often frustrate overseas buyers.

Proven Track Record: We have served globally renowned brands including Opti and American brand USPA. Our experience with premium brands demonstrates our capability to meet the most demanding quality requirements.

End-to-End Solutions: From initial sample development through mass production, we provide complete one-stop solutions. Our team understands the unique challenges overseas brands face when sourcing from China, and we have designed our processes to eliminate these frustrations.

Our commitment extends beyond manufacturing. We deliver certainty, quality, and true partnership to every client relationship.

Conclusion

Zipper engineering represents elegant mechanical design perfected over decades. The Y-shaped wedge system, precise tooth geometry, and rigorous testing standards work together to create reliable fastening solutions. Understanding these principles helps us appreciate why quality matters in zipper manufacturing and selection.

Ready to source premium zippers with guaranteed quality? At Holyn Textile, we combine advanced manufacturing capabilities with personalized service to deliver zipper solutions that exceed expectations. Contact us today for samples and technical specifications.

Get in touch: holyntextile.com | Email: [email protected]

Holyn Textile - High Links High Standard

Understanding the Y-shaped wedge system is crucial for grasping how zippers function effectively. ↩

Exploring compression force will enhance your knowledge of the mechanics behind zipper operation. ↩

This resource will provide insights into the role of precision engineering in manufacturing high-quality zippers. ↩

Exploring this link will deepen your understanding of zipper design and its impact on functionality. ↩

Understanding force distribution can enhance your knowledge of zipper durability and performance. ↩

Exploring angle precision reveals how design impacts zipper functionality and longevity. ↩

Exploring quality control in zipper manufacturing reveals how it ensures durability and reliability in products. ↩

Understanding tooth misalignment can help you prevent zipper jams and extend the life of your zippers. ↩

Understanding tooth misalignment can help you prevent zipper failures and improve durability. ↩

Exploring material fatigue will provide insights into zipper longevity and the importance of quality in manufacturing. ↩

Explore this link to understand how fatigue testing ensures zipper durability and performance under stress. ↩

Learn about salt spray testing to see how it protects zippers from corrosion in harsh environments. ↩